Wire Weaving by Sarah Thompson

Wire weaving is a fun way to turn simple wire into beautiful, creative designs. In this easy-to-follow guide, Sarah Thompson shares her tips on how to become great at wire weaving, with step-by-step instructions that even beginners can use.

Whether you're crafting a woven wire cabochon ring or experimenting with a modified Soumak weave, this guide gives you the tools and ideas to improve your jewelry-making skills.

The most important thing to remember is that practice makes perfect-your weaving will get better and better the more you do.

Jump to section:

Whether you're crafting a woven wire cabochon ring or experimenting with a modified Soumak weave, this guide gives you the tools and ideas to improve your jewelry-making skills.

The most important thing to remember is that practice makes perfect-your weaving will get better and better the more you do.

Jump to section:

Instructions

Introduction to Wire Weaving

Wire weaving has seen a surge in popularity over the last five years, with intricate jewelry designs emerging from artists worldwide.

A decade ago, when I first explored this art, finding resources on wire weaving, especially for finer gauges like 28 and 30, was challenging.

Most available content focused on wire wrapping with heavier wires, which are traditionally used for capturing stones, making findings, and creating simpler designs with loops and twists.

A decade ago, when I first explored this art, finding resources on wire weaving, especially for finer gauges like 28 and 30, was challenging.

Most available content focused on wire wrapping with heavier wires, which are traditionally used for capturing stones, making findings, and creating simpler designs with loops and twists.

Wire weaving, however, shifts the focus to intricate design work, using beads and stones to complement the overall piece.

By weaving heavier base wires, you create a platform that can be embellished with finer wires, eliminating the need for soldering.

I often work with fine silver because its softness allows for better shaping, while the weaving itself provides the strength needed to hold everything in place.

By weaving heavier base wires, you create a platform that can be embellished with finer wires, eliminating the need for soldering.

I often work with fine silver because its softness allows for better shaping, while the weaving itself provides the strength needed to hold everything in place.

Different wire weaving techniques, many inspired by traditional basket and rug weaving, enable a range of textures and patterns.

By varying wraps, lashings, and the direction of the weave, artists can create unique designs. The possibilities are constantly expanding as more artists experiment with these techniques.

By varying wraps, lashings, and the direction of the weave, artists can create unique designs. The possibilities are constantly expanding as more artists experiment with these techniques.

In my teaching, I emphasize the importance of choosing the right wire for the job. Using softer wires can prevent frustration during shaping, a common struggle among beginners.

With the right wire and techniques, wire weaving opens up endless creative possibilities.

With the right wire and techniques, wire weaving opens up endless creative possibilities.

Choosing the Best Wire for Weaving

- Soft and buttery, making it easy to shape.

- Melts smoothly with a torch, without creating firescale.

- Ideal for weaving due to its compacting ability and lack of springiness, resulting in a tighter weave.

- Hardens quickly, which limits reshaping for more complex designs.

- Bends are more permanent compared to fine silver, which can be straightened and reshaped.

- Best used as a base wire for added rigidity, especially in bracelets or rings.

- For intricate bracelets, a combination of fine silver (for weaving) and sterling silver (as the base wire) works best.

- Soft and malleable, though its softness can vary depending on the supplier.

- Similar to sterling silver in terms of workability but tends to be softer, making shaping easier.

- A cost-effective alternative to silver.

- Difficult to shape, even when dead soft.

- The wire tends to have more spring, making it harder to compact in weaves.

- Prone to scratching but useful for adding pops of color in weaves when using smaller gauge wires.

Fine Silver Wire:

Choosing the Right Wire Gauge Size for Weaving and Embellishments

- I like to break my gauges into 3 categories. These categories include the base wires (14g-20g) used for structural support, mid-range wires (22g-26g) used for embellishments, and fine wires (28g-30g) for weaving intricate designs.

- 14g - 16g: Creates a great backbone if you want to weave pre-shaped wires together. It helps provide more strength to an open, airy design.

- 18g - 20g: Easier to manipulate and shape into elaborate designs. By intermixing the gauges, you get the strength of thicker wires with the fine details of smaller gauged wires.

- 22g - 26g: These gauges are great for adding beads to finished forms, creating head pins, links, and wrapping briolettes-essentially for all things related to embellishments.

- 28g - 30g: These are the wires used for weaving. You can weave with 26g and 24g wire, but for a fine-textured weave, 28g and 30g are ideal. I've also found that these gauges are much easier on the hands.

Each category has specific uses that balance strength, flexibility, and detail in jewelry making.

Step-by-Step Guide: How to Create the Modified Soumak Weave

Instructions - The Weave:

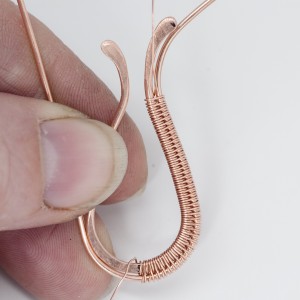

The modified Soumak weave is my favorite weave. It is versatile and produces a consistent, tight weave with uniform spacing between the base wires.

Materials:

Cut four 5 inch lengths of practice wire in 18ga. Use 30ga wire to weave with.

The modified Soumak weave is my favorite weave. It is versatile and produces a consistent, tight weave with uniform spacing between the base wires.

Materials:

Cut four 5 inch lengths of practice wire in 18ga. Use 30ga wire to weave with.

Start Left to Right:

1. We will start by weaving left to right.

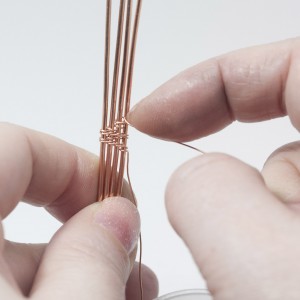

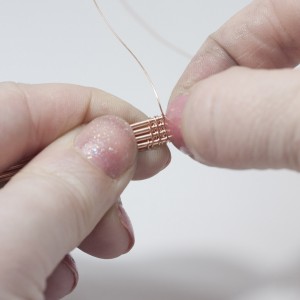

2. Leaving a 6 inch tail, bring the rest of your 30ga wire to the back of all four base wires. Photo (1)

3. Thread the 30ga wire between wires 1 and 2. Photo (2)

Wrap the 30ga wire around wire 1, going clockwise, bringing the 30ga wire to the back of the base wires. Photo (3)

Go to the right side of wire 2 and thread the 30ga wire between wires 2 and 3. Photo (4)

Wrap the 30ga wire completely around wire 2, going clockwise, bringing the 30ga wire to the back of the base wires. Photo (5)

Bring the 30ga wire to the right side of wire 3 and thread the 30ga wire between wires 3 and 4.Photo (6)

Completely wrap around wire 3, going clockwise, bringing the 30ga wire to the back of the base wires once more. Photo (7)

Bring the 30ga wire to the right side of wire 4 and completely wrap around wire 4, going clockwise, bringing the 30ga wire to the back of the base wires once more. Photo (8)

.jpg)

Going Right to Left:

You will now be weaving back across the front going right to left. Your 30ga wire should be in the back of wire 4, bring it to the front. Photo (1)

.jpg)

Get started wire weaving today with these FREE Jewelry-Making Tutorials:

Jump to section:

Materials

18 Gauge Half Round Half Hard Copper Wire

H11-18HRH

- Lesson Quantity: 3.00 feet

- Purchase Quantity: 1.00 5FT

- Price: $2.61

- Gold Club Price: $1.95

30 Gauge Round Dead Soft Copper Wire - 1LB

H11-30D-1LB

- Lesson Quantity: 25.00 ounces

- Purchase Quantity: 1.00 each

- Price: $32.15

- Gold Club Price: $24.11

Tools

C.H.P Milano Italian Flush Cutter, 5 1/2 Inches

PLR-487.00

- PLR-487.00

- Lesson Quantity: 1.00 pieces

- Purchase Quantity: 1.00 each

- Price: $16.97

- Gold Club Price: $12.73

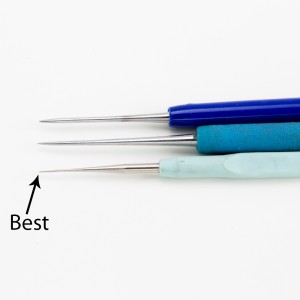

Straight Steel Pick

CVR-400.30

- CVR-400.30

- Lesson Quantity: 1.00 pieces

- Purchase Quantity: 1.00 each

- Price: $3.95

- Gold Club Price: $2.96

Flat Nose Wire Pliers

G2-506

- G2-506

- Lesson Quantity: 1.00 pieces

- Purchase Quantity: 1.00 each

- Price: $32.95

- Gold Club Price: $24.71

Round Nose Wire Pliers

G2-507

- G2-507

- Lesson Quantity: 1.00 pieces

- Purchase Quantity: 1.00 each

- Price: $32.95

- Gold Club Price: $24.71

Adjustable Headband Magnifier with Light

G6-7

- G6-7

- Lesson Quantity: 1.00 pieces

- Purchase Quantity: 1.00 each

- Price: $33.95

- Gold Club Price: $25.46

- Category: Weaving

- Technique(s): Wrapping, Weaving, General Education

Avoiding Hand Fatigue and Chafing

Avoiding Hand Fatigue and Chafing

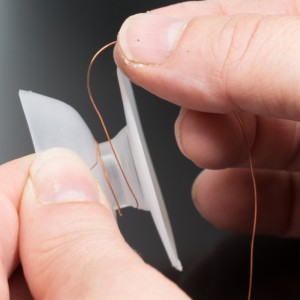

Plexiglas stencils

Plexiglas stencils

Wire Weaving

Wire Weaving

Holding Wire for Weaving

Holding Wire for Weaving

Keeping the Kinks Out of Your Wire

Keeping the Kinks Out of Your Wire

Keeping Wire Tangle Free

Keeping Wire Tangle Free

My Favorite Tool

My Favorite Tool

Quick Project Storage

Quick Project Storage

Creating Symmetry in Design

Creating Symmetry in Design

Weaving Long Lengths of Wire

Weaving Long Lengths of Wire

How to Compress Your Weave

How to Compress Your Weave