Hammering Heavy Gauge Wire

Hammering not only hardens the wire, it also adds an attractive contrast in textures with round and flattened wire. The hammered wire also makes binding or lashing easier, as the thinner wire holds its position firmly against the flattened edges.

Instructions

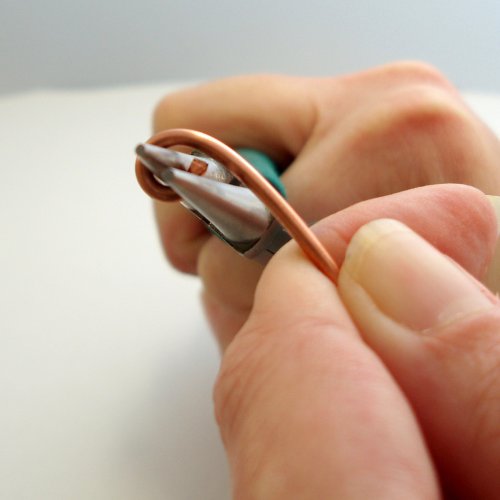

Place a shaped piece of 12-gauge wire on your bench block or anvil.

Hold it in place with your non-dominant hand and begin hammering with the smooth head of your hammer.

Start at the center of the spiral and work your way methodically around the shape.

For added contrast, I like to hammer the outer rotation of the spirals slightly more than the center loop.

Use many small taps instead of heavy blows to ensure a smooth, even finish as you follow the wire's curve.

Hold it in place with your non-dominant hand and begin hammering with the smooth head of your hammer.

Start at the center of the spiral and work your way methodically around the shape.

For added contrast, I like to hammer the outer rotation of the spirals slightly more than the center loop.

Use many small taps instead of heavy blows to ensure a smooth, even finish as you follow the wire's curve.

Notice how hammering can cause the loops in your spiral to open slightly.

Notes on Hammering:

• Make sure the front face of your wire shape is against the bench block or anvil so that side stays smooth.

• Hammer the wire evenly to maintain a consistent, balanced look throughout the design.

• Keep your hammer head perfectly flat against the bench block when striking. Hitting at an angle will distort the wire's shape.

If you strike the outer edge of the wire, you'll push the spiral tighter.

Notes on Hammering:

• Make sure the front face of your wire shape is against the bench block or anvil so that side stays smooth.

• Hammer the wire evenly to maintain a consistent, balanced look throughout the design.

• Keep your hammer head perfectly flat against the bench block when striking. Hitting at an angle will distort the wire's shape.

If you strike the outer edge of the wire, you'll push the spiral tighter.

By striking the inner edge of the wire, you'll force the spiral to open.

This happens because hammering flattens the top and bottom of the wire, pushing the metal outward.

If you don't apply even pressure, one side will expand more than the other sometimes a useful effect, if intentional.

• An angled hammer head can leave marks in the wire.

• As you hammer, the metal may begin to curve upward slightly.

This happens because hammering flattens the top and bottom of the wire, pushing the metal outward.

If you don't apply even pressure, one side will expand more than the other sometimes a useful effect, if intentional.

• An angled hammer head can leave marks in the wire.

• As you hammer, the metal may begin to curve upward slightly.

Materials

10 Gauge Round Dead Soft Copper Wire

H11-10D

- Lesson Quantity: 5.00 feet

- Purchase Quantity: 1.00 5FT

- Price: $24.99

- Gold Club Price: $18.75

Tools

Chasing Hammer with Wooden Handle, 1 1/8 Inch Face

G3-27

- G3-27

- Lesson Quantity: 1.00 pieces

- Purchase Quantity: 1.00 each

- Price: $13.95

- Gold Club Price: $10.46

Flat Face Chasing Hammer

HAM-161.00

- HAM-161.00

- Lesson Quantity: 1.00 pieces

- Purchase Quantity: 1.00 each

- Price: $14.97

- Gold Club Price: $11.23

Steel and Rubber Bench Block 4x4 Inches

G17-44

- G17-44

- Lesson Quantity: 1.00 pieces

- Purchase Quantity: 1.00 each

- Price: $29.95

- Gold Club Price: $22.46

- Category: General Education

- Technique(s): Forging, Tools

Making a Wrapped Briolette

Making a Wrapped Briolette

Make a Quick End Cone

Make a Quick End Cone

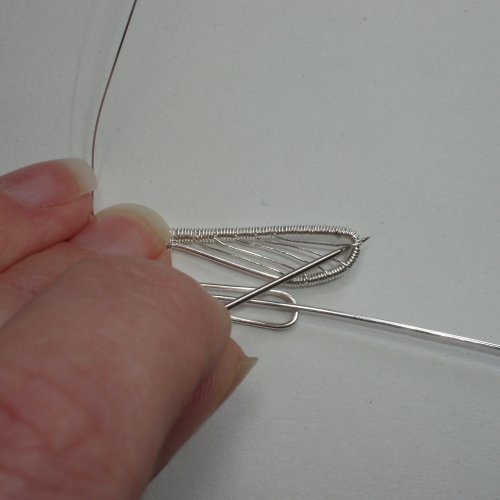

Wire Weaving Tips

Wire Weaving Tips

Working with Long Lengths of Wire

Working with Long Lengths of Wire

Tips for Working with Heavy Gauge Wire

Tips for Working with Heavy Gauge Wire

Straightening Wires Already Woven

Straightening Wires Already Woven

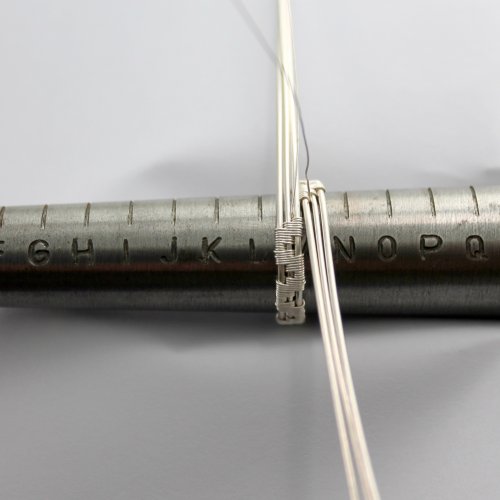

How to Use a Tapered Ring Mandrel

How to Use a Tapered Ring Mandrel

Keeping Warp or Base Wires Separate

Keeping Warp or Base Wires Separate

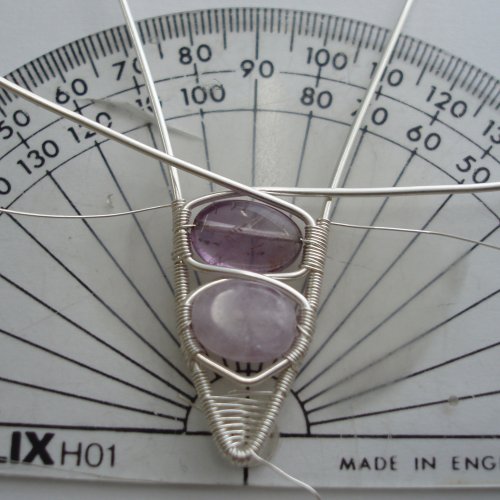

Using a Protractor to Keep Wires Straight

Using a Protractor to Keep Wires Straight

Making Loops with Heavy Gauge Wire

Making Loops with Heavy Gauge Wire

test tip

test tip