Finding Draw Plate Gauge

Question:

Hi, I'm wondering what the gauges are in wire jewelry, and what the increment between each gauge is. I have a draw plate, but the holes aren't marked, so I don't know the sizes or increments. Thank you.

Hi, I'm wondering what the gauges are in wire jewelry, and what the increment between each gauge is. I have a draw plate, but the holes aren't marked, so I don't know the sizes or increments. Thank you.

Instructions

Answer:

Hi Mollie,

Most wire jewelry uses gauges ranging from 14-gauge (thick) to 28-gauge (thin), though some designs may use even thicker or thinner wire.

The higher the number, the thinner the wire. I remember it by picturing a small tube lots of thin wires like 28-gauge can fit, but only a few thick ones like 12-gauge.

Wire jewelry patterns typically use even-numbered gauges, plus 21-gauge.

In North America, wire is usually measured using the American Wire Gauge (AWG) system.

Wikipedia offers helpful details on how this system works, including how sizes are calculated and some handy rules of thumb.

Here on WireJewelry.com, we have a handy page for finding the diameter (width) of the wire in inches and millimeters. Simply go to our Resource Center and look under "All About Wire" it's called Wire Gauge & Footage Charts. The first two charts are for converting the weight of wire to footage (because some people are used to ordering wire by the ounce or the pound, and we offer jewelry wire by the foot); the last chart will help you convert AWG to inches and millimeters.

To determine the gauge of a hole in your draw plate, measure its diameter using a millimeter ruler, wire gauge tool, or caliper.

Then, use the chart I mentioned earlier to convert the millimeter measurement to AWG.

Keep in mind that many draw plates are chamfered, meaning the hole is wider at the entry point and tapers to a smaller finished size.

I hope this helps!

Hi Mollie,

Most wire jewelry uses gauges ranging from 14-gauge (thick) to 28-gauge (thin), though some designs may use even thicker or thinner wire.

The higher the number, the thinner the wire. I remember it by picturing a small tube lots of thin wires like 28-gauge can fit, but only a few thick ones like 12-gauge.

Wire jewelry patterns typically use even-numbered gauges, plus 21-gauge.

In North America, wire is usually measured using the American Wire Gauge (AWG) system.

Wikipedia offers helpful details on how this system works, including how sizes are calculated and some handy rules of thumb.

Here on WireJewelry.com, we have a handy page for finding the diameter (width) of the wire in inches and millimeters. Simply go to our Resource Center and look under "All About Wire" it's called Wire Gauge & Footage Charts. The first two charts are for converting the weight of wire to footage (because some people are used to ordering wire by the ounce or the pound, and we offer jewelry wire by the foot); the last chart will help you convert AWG to inches and millimeters.

To determine the gauge of a hole in your draw plate, measure its diameter using a millimeter ruler, wire gauge tool, or caliper.

Then, use the chart I mentioned earlier to convert the millimeter measurement to AWG.

Keep in mind that many draw plates are chamfered, meaning the hole is wider at the entry point and tapers to a smaller finished size.

I hope this helps!

Materials

Wire

Tools

Wire Gauge by Euro Tool

GAU-144.10

- GAU-144.10

- Lesson Quantity: 1.00 pieces

- Purchase Quantity: 1.00 each

- Price: $13.97

- Gold Club Price: $10.48

- Category: General Education

- Technique(s): Wrapping

You Will Never Use a Flex Shaft Again

You Will Never Use a Flex Shaft Again

Wire Working Basics

Wire Working Basics

How to Use Liver of Sulfur

How to Use Liver of Sulfur

Beading Wire

Beading Wire

Stone Setting and Burnishers Wire Jewelry Tool Tip

Stone Setting and Burnishers Wire Jewelry Tool Tip

Handmade Venetian Glass Beads

Handmade Venetian Glass Beads

Basic Wire Wrapping Formulas

Basic Wire Wrapping Formulas

Featured Tool - Small Benchtop Drill Press

Featured Tool - Small Benchtop Drill Press

Colored Craft Wire Creations

Colored Craft Wire Creations

Creating with Handmade Venetian Glass Beads

Creating with Handmade Venetian Glass Beads

Crystal Skulls Mysterious and Beautiful

Crystal Skulls Mysterious and Beautiful

Crystal Skulls are Skyrocketing

Crystal Skulls are Skyrocketing

What are Abalone and Paua Shells

What are Abalone and Paua Shells

Button Wire Jewelry Ideas

Button Wire Jewelry Ideas

Copyright and Wire Jewelry Designs

Copyright and Wire Jewelry Designs

Designing Bold Summer Bracelets

Designing Bold Summer Bracelets

Dual Size Round Nose Pliers

Dual Size Round Nose Pliers

EnCapture Artisan Concrete and Open Back Bezels

EnCapture Artisan Concrete and Open Back Bezels

Featured Tool - AccuLoop Precision Pliers

Featured Tool - AccuLoop Precision Pliers

Featured Tool - Heetrix Soldering Platform

Featured Tool - Heetrix Soldering Platform

Featured Tool- Miland Pliers

Featured Tool- Miland Pliers

Featured Tool - C.H.P Milano Italian Flush Cutters

Featured Tool - C.H.P Milano Italian Flush Cutters

Featured tool - Wire Cutters for every work bench

Featured tool - Wire Cutters for every work bench

Featured Tool - Wax Casting Supplies

Featured Tool - Wax Casting Supplies

Helping your Silver Jewelry Survive the Summer

Helping your Silver Jewelry Survive the Summer

Inspired Wire Creations by Patti Bullard

Inspired Wire Creations by Patti Bullard

Jewelry Making Design Tips

Jewelry Making Design Tips

Featured Tool - Sheet Metal Disc Cutter

Featured Tool - Sheet Metal Disc Cutter

Double Wrapped Loop

Double Wrapped Loop

Magnifying Tools

Magnifying Tools

Make Your Own Jewelry to Match Whatever

Make Your Own Jewelry to Match Whatever

Featured Tool - Mandrels

Featured Tool - Mandrels

Featured Tool - Jumbo Tapered Round Wubbers

Featured Tool - Jumbo Tapered Round Wubbers

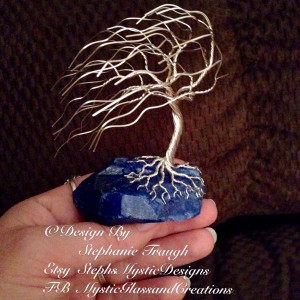

Planting Trees

Planting Trees

Pointers To Get The Attention At The Craft Show

Pointers To Get The Attention At The Craft Show

Quick Holiday Gifts

Quick Holiday Gifts

Spring Cleaning... Ring Cleaning

Spring Cleaning... Ring Cleaning

Texturing with everyday objects

Texturing with everyday objects

The Birth of 200 Thousand Jump Rings

The Birth of 200 Thousand Jump Rings

Tips for Wire Wrapping a Cameo

Tips for Wire Wrapping a Cameo

What is a Bead Reamer

What is a Bead Reamer

What is a Rotary Tool

What is a Rotary Tool

What type of Wire Should I Use

What type of Wire Should I Use

6 InsPIrations for Pi Day

6 InsPIrations for Pi Day

Coating Base Metal Wires to Preserve Shine

Coating Base Metal Wires to Preserve Shine

Try, Try Again

Try, Try Again

How Many Beads in a Strand

How Many Beads in a Strand

Jump Ring Measurements

Jump Ring Measurements

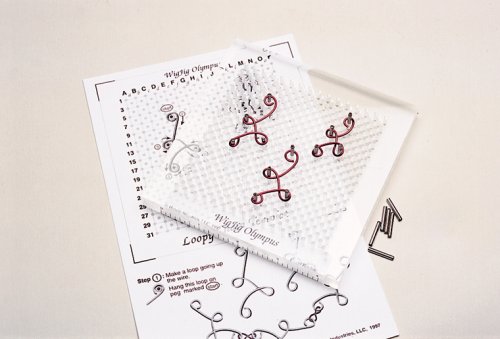

What is a Jig

What is a Jig

Birthstones and Gemstone Chart

Birthstones and Gemstone Chart

How to Make Square Spirals

How to Make Square Spirals

111111 Restock Faster with My Account Feature - needs updating

111111 Restock Faster with My Account Feature - needs updating

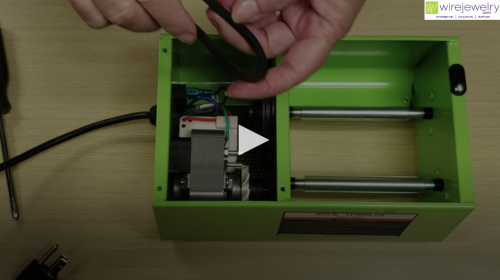

How to change the belt on your Tumbler

How to change the belt on your Tumbler

Test Gavin

Test Gavin

Top 5 Weaves for Chain Mail Beginners

Top 5 Weaves for Chain Mail Beginners

What Does 14-20 Gold Filled Mean

What Does 14-20 Gold Filled Mean

Why is my Sterling Silver Magnetic

Why is my Sterling Silver Magnetic

Brazed Armature Pendant

Brazed Armature Pendant

Make Perfect Loops Settings For Your Projects with Skewers

Make Perfect Loops Settings For Your Projects with Skewers