Wire Bangles

- Category: Contemporary

- Technique(s): Butane Torch Techniques

- Skill Level: Beginner

My daughter loves bangles but, just like me, has smaller than average hands and wrists so purchased bangles are WAY too large. I made a set of 3 silver, 1 gold and 1 rose gold bangles to fit her and she wears them every day. Change the number of bangles, the gauges of wire and the types of metals to suit your tastes.

Materials

10 Gauge Round Dead Soft Argentium .940 Silver Wire

H19-10D

- Lesson Quantity: 3.00 feet

- Purchase Quantity: 1.00 5FT

- Price: $180.97

- Gold Club Price: $135.72

Silver Solder Paste Medium SS70 - 1/4 T.O.

SOL-822.15

- Lesson Quantity: 1.00 pieces

- Purchase Quantity: 1.00 each

- Price: $18.95

- Gold Club Price: $14.21

Silver Solder Paste Soft SS65- 1/4 T.O.

SOL-822.10

- Lesson Quantity: 1.00 pieces

- Purchase Quantity: 1.00 each

- Price: $16.95

- Gold Club Price: $12.71

Tools

Handy Flame Butane Torch

SOL-315.00

- SOL-315.00

- Lesson Quantity: 1.00 pieces

- Purchase Quantity: 1.00 each

- Price: $29.95

- Gold Club Price: $22.46

7 Piece Mini TruStrike Hammer Set with Stand

HAM-520.70

- HAM-520.70

- Lesson Quantity: 1.00 pieces

- Purchase Quantity: 1.00 each

- Price: $140.54

- Gold Club Price: $105.40

Medium Rawhide Hammer 1 1/4 inch - Pack of 1

G3-7

- G3-7

- Lesson Quantity: 1.00 pieces

- Purchase Quantity: 1.00 each

- Price: $32.95

- Gold Club Price: $24.71

Instructions

Step 1

Unfortunately, I was a bit distracted when I was making one of the bangles and instead of soldering the ends together, I heated the join a bit too long and melted the ends apart. Since my hands do not bend like they used to, I can no longer wear bangles, just cuffs. So, the "OOPS" turned into a nice little cuff for me-Yay!

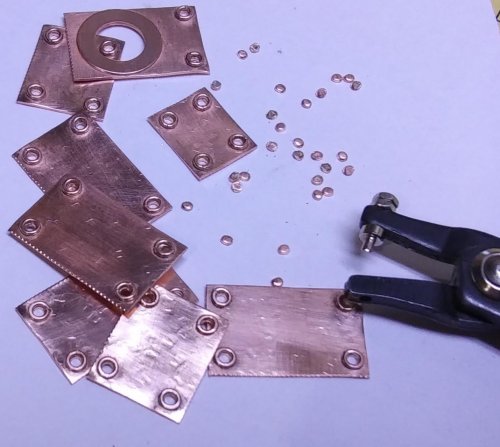

How do I know what size to make? Hint: Make a single copper bangle, very inexpensive to make, in each of the sizes you might make. Attach a size charm to each one. The best way to determine size it to measure a bangle that fits. See Step 10.

How do I know what size to make? Hint: Make a single copper bangle, very inexpensive to make, in each of the sizes you might make. Attach a size charm to each one. The best way to determine size it to measure a bangle that fits. See Step 10.

Step 2

Read through all the directions before beginning the project.

Use heavy duty cutters or aviation shears, shown here, to cut 10 gauge round wire to the length needed for the chosen bangle size. Memory wire cutters will make a more flat cut so less filing will be needed before soldering.

Size XX-Small 6-5/8" X-Small 6-7/8" Small 7 ¼" Medium 7¾" Large 8-1/8" X-Large 8-3/8"

If a plain wire bangle with no texture is desired, cut 10 gauge wire longer slightly than needed. File to the length listed.

Size XX-Small 7-5/16" X-Small 7-23/32" Small 8-3/32" Medium 8-15/32" Large 8-27/32" X-Large 9 ¼"

Use heavy duty cutters or aviation shears, shown here, to cut 10 gauge round wire to the length needed for the chosen bangle size. Memory wire cutters will make a more flat cut so less filing will be needed before soldering.

Size XX-Small 6-5/8" X-Small 6-7/8" Small 7 ¼" Medium 7¾" Large 8-1/8" X-Large 8-3/8"

If a plain wire bangle with no texture is desired, cut 10 gauge wire longer slightly than needed. File to the length listed.

Size XX-Small 7-5/16" X-Small 7-23/32" Small 8-3/32" Medium 8-15/32" Large 8-27/32" X-Large 9 ¼"

Step 3

So a perfect solder join can be made, the ends of each wire must be perfectly flat. In a perfect world, there would be access to a Miter Joint Jig Vise. Secure one end of the wire in the larger diamond shaped opening in the vice so the portion with cut marks can be removed. File the end of the wire flat, flush with the surface of the vise. Repeat with the other end of the wire. Note: The vise used here is for 45 and 90 degree angles. Use the flat 90 degree portion.

If a Miter Joint Jig Vise is not available, a pair of flat nose pliers will work. Place the wire as close as possible to the fulcrum of the pliers. This area will provide a 90 degree angle for the wire end to be filed flat. This will also allow for less pressure needed to grip the handles of the pliers to hold the wire and less chance of marring the wire. Hint: Wrap electricians tape around the jaws of the pliers to help prevent marring. Place the end of the plier jaws on the edge of the work surface. File the wire flat and flush with the top of the pliers.

Step 4

Bend the wire into an oval shape, matching the ends up as perfectly as possible. No light should be seen between the ends from any angle. Hint: Forming the wire into a "smile" and then pulling the wires back so the ends touch can help to create a flush connection between the wire ends.

Step 5

Place a small amount of paste solder on the join. Solder the join closed. Remove the heat immediately after the solder flows. Wait for the unit to cool a bit before quenching. Hint: Quenching immediately after soldering can split the join so wait a bit before placing the bangle in water to cool it.

Pro Tip: Because this is a larger piece and a heavy gauge wire, a small butane micro-torch will not work. Butane can still be used if the flame is larger, as with this torch head which attached to a butane canister used in camping.

Step 6

Pickle the piece to remove fire scale. 320 grit sandpaper can be used to clean excess solder around the join.

Step 7

Use bracelet bending pliers to round the bangle. Start at the join and work outward around the entire bangle. The bangle does not need to be a perfect circle, just oval enough to fit over the end of the bracelet mandrel.

Step 8

Slide the bangle loosely down onto a bracelet mandrel. Strike the bangle with a rawhide mallet to help round it. Keep turning the mandrel until the bangle is round.

Step 9

Place the bangle on a bench block. Strike the bangle using rawhide mallet until it is flat.

Step 10

It is time to make a design decision: What texture hammer should be used on the bangle? The bangle on the left was textured with a Mini TruStrike Sharp Designer Hammer and the one on the right was textured with a large domed face hammer (a Mini TruStrike Planishing Hammer could also be used).

Step 11

Texture the outside of the bangle as well as the top and bottom. If using a texturing hammer other than a domed face one, use the domed face hammer to stretch the metal until it is at least halfway to the desired diameter. There will be less chance of splitting the bangle that way. A Sharp Raising Hammer does not move or expand metal as fast as a domed face hammer. The bangle also gets larger faster when hammered on a bench block. Check the size often.

Hammer out to an inside diameter of: XX-Small: 2¼" X-Small 2-3/8" Small 2½" Medium 2-5/8 Large 2¾" X-Large 2-7/8"

Pro Tip: Measure the diameter with a clear ruler both horizontally (shown) and vertically until the desired size is reached.

Pro Tip: When making multiples, slide a finished bangle on the bracelet mandrel. Use a fine point Sharpie marker to draw a line above and below it. It will then be easy to tell when the bangle is getting close to the desired size.

Step 12

Tumble the bangle in steel shot, water and a drop of dish liquid to work harden it and bring up a beautiful shine.

Step 13

Leave the bangle bright and shiny, in which case the bangle is done. Or use liver of sulfur to patina the bangle. Buff with 0000 steel wool to bring out the dimension of the texturing.

Step 14

What about that OOPS! Cuff? I was making an XX-Small Argentium silver bangle when I OOPSED. I then alternated melting the silver ends until the wire measured a scant 6" long, a hair more than 5/8" shorter than the original length. The 5/8" shorter can be done for all the sizes.

Cut 10-gauge wire for size: XX-Small 6-5/8" X-Small 6-7/8" Small 7 ¼" Medium 7¾" Large 8-1/8" X-Large 8-3/8"

Melt ends to length of: XX-small 6" X-small 6¼" Small 6-5/8" Medium 7-1/8" Large 7½" X-large 7¾"

Melt ends to length of: XX-small 6" X-small 6¼" Small 6-5/8" Medium 7-1/8" Large 7½" X-large 7¾"

Step 15

Place the balled end wire on a bench block and straighten it using a rawhide mallet. Keep turning the wire on the block to make sure it is as straight as possible.

Step 16

Place the wire, flat side of the balled ends facing up, under one of the sections on the stepped bracelet mandrel. Form the wire around that step.

Step 17

Use bracelet bending pliers to finesse the shape to better fit a wrist. Hint: Place the cuff on a grid to check symmetry.

Step 18

Tumble the bangle in steel shot, water and a drop of dish liquid to work harden it and bring up a beautiful shine.

Step 19

Leave the bangle bright and shiny, in which case the bangle is done. Or use liver of sulfur to patina the bangle. Buff with 0000 steel wool to bring out the dimension of the texturing.

Step 20

Buffing with steel wool creates a satin finish on the metal. If desired, tumble the pieces for about 30 minutes to bring up a shine. Tumbling will not affect the patina.

Oh, the possibilities! Consider twisting two 14- or 12-gauge wires together to make this cuff. Or maybe twist a single 8- or 10-gauge square wire. Flattening twisted wire slightly would make a beautiful cuff. Placing two wires side by side would be beautiful, as well. If the balled ends are flattened slightly, they can be stamped.

Beaded Briolette Pendant

Beaded Briolette Pendant Snail Trail Spiral Earrings

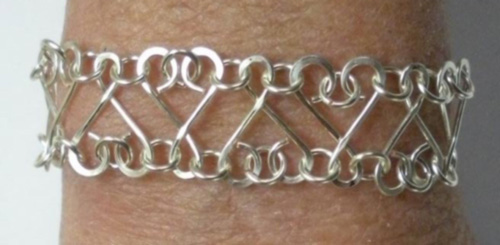

Snail Trail Spiral Earrings Heart Link Bracelet and Earrings

Heart Link Bracelet and Earrings Crazy Hoop Earrings

Crazy Hoop Earrings Double Delight Jade Bracelet

Double Delight Jade Bracelet Swagged Pearl Pendant

Swagged Pearl Pendant Heart Earrings with Drops

Heart Earrings with Drops Scarab Bracelet

Scarab Bracelet Birthstone Heart Pendant

Birthstone Heart Pendant Pearl of the Sea Woven Pendant

Pearl of the Sea Woven Pendant Bead Charm

Bead Charm Coiled Rosette Link

Coiled Rosette Link Wire Jewelry Component and Swan Hook

Wire Jewelry Component and Swan Hook Leaf Bail

Leaf Bail  Component Templates with Heart Earrings and Pendant

Component Templates with Heart Earrings and Pendant Ring Pendant

Ring Pendant Calla Lily Earrings

Calla Lily Earrings Birdhouse Pendant

Birdhouse Pendant Clamshell Earrings and Pendant

Clamshell Earrings and Pendant Bracelet Component

Bracelet Component Teardrop Earrings and Pendant

Teardrop Earrings and Pendant Tab Style Pendant

Tab Style Pendant Coiled End Caps

Coiled End Caps Freeform Pendant

Freeform Pendant French Hook Ear Wires

French Hook Ear Wires Necklace Component

Necklace Component Triangle Shield Earrings, Pendant and Bail

Triangle Shield Earrings, Pendant and Bail How to Make a Wire Coil and Bead

How to Make a Wire Coil and Bead Egyptian Coil Bracelet

Egyptian Coil Bracelet Focal Bead Egyptian Coiled Bracelet

Focal Bead Egyptian Coiled Bracelet Sweetheart Round Cabochon Pendant

Sweetheart Round Cabochon Pendant Making Cobblestone Cabochons

Making Cobblestone Cabochons Cupcake Wrapper Earrings

Cupcake Wrapper Earrings How to Make Metal Washers

How to Make Metal Washers Baseball Skin Keychain

Baseball Skin Keychain Pat's Silver Domed Earrings

Pat's Silver Domed Earrings Blaze Your Own Path Pendant

Blaze Your Own Path Pendant Semi Snap-on Bail

Semi Snap-on Bail Interlocking Faux Twist Wire Bracelet

Interlocking Faux Twist Wire Bracelet Fold Formed Cuff With Faux Roman Glass or Coin Cabochon

Fold Formed Cuff With Faux Roman Glass or Coin Cabochon Steampunk Style Leaf Earrings

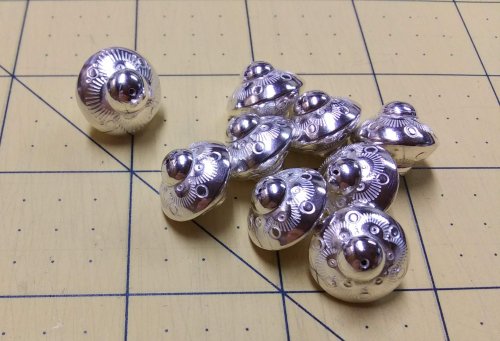

Steampunk Style Leaf Earrings Stamped Saucer Beads

Stamped Saucer Beads Kat's Wire Hoop Earrings

Kat's Wire Hoop Earrings Simple Bail on a Coin Pendant

Simple Bail on a Coin Pendant Rolling Mill - or not - Cuff Bracelet

Rolling Mill - or not - Cuff Bracelet Jen's Chain

Jen's Chain Making Neckwires

Making Neckwires Silver Scrap Wire Focals to Embellish

Silver Scrap Wire Focals to Embellish Splash Ring

Splash Ring Cobblestone Cab Earrings

Cobblestone Cab Earrings Multi Gemstone Necklace

Multi Gemstone Necklace Southwest Style Pendant

Southwest Style Pendant Bezels Using Square Wire

Bezels Using Square Wire Mixed Metal Sampler Bracelet 1

Mixed Metal Sampler Bracelet 1 Mixed Metal Sampler Bracelet 2

Mixed Metal Sampler Bracelet 2 Mixed Metal Sampler Bracelet 3

Mixed Metal Sampler Bracelet 3 Mixed Metal Sampler Bracelet 4 - Words Matter

Mixed Metal Sampler Bracelet 4 - Words Matter Mixed Metal Sampler Bracelet 5 - River Walk

Mixed Metal Sampler Bracelet 5 - River Walk  Mixed Metal Sampler Bracelet 6 - A Little Bling

Mixed Metal Sampler Bracelet 6 - A Little Bling Mixed Metal Sampler Bracelets Series PUTTING IT ALL TOGETHER

Mixed Metal Sampler Bracelets Series PUTTING IT ALL TOGETHER  Mixed Metal Sampler Bracelet 7 - Steampunk Space Oddity

Mixed Metal Sampler Bracelet 7 - Steampunk Space Oddity Mixed Metal Sampler Bracelet 8 - Fun Shapes

Mixed Metal Sampler Bracelet 8 - Fun Shapes Jump Ring Fringe Bracelet

Jump Ring Fringe Bracelet Easy Artisan Earrings

Easy Artisan Earrings Making Chain with Wubbers and Wire

Making Chain with Wubbers and Wire Heirloom Buttons and Beads Bracelet

Heirloom Buttons and Beads Bracelet  Tiny Silver Charms part 1

Tiny Silver Charms part 1 Argentium Silver Scrap Chain

Argentium Silver Scrap Chain Sterling Lake Stone Pendant with Twisted Wire

Sterling Lake Stone Pendant with Twisted Wire Smashing Drop Earrings

Smashing Drop Earrings Argentium Silver Scrap Nugget Cuff

Argentium Silver Scrap Nugget Cuff Finish Them Your Way Earrings

Finish Them Your Way Earrings Paddle Fringe Earrings

Paddle Fringe Earrings Seed Bead Earrings

Seed Bead Earrings Bracelet Links 1, 2,3

Bracelet Links 1, 2,3 Stamped Saucer Beads

Stamped Saucer Beads Chaos Scrap Wrap Jewelry

Chaos Scrap Wrap Jewelry Maple Leaf Earrings

Maple Leaf Earrings Child's Bracelet That Grows with Them

Child's Bracelet That Grows with Them Mike's Surpirise Claire's Ripple Pendant

Mike's Surpirise Claire's Ripple Pendant Angel Ornament

Angel Ornament  Diamonds, Emeralds, and Sapphires, Oh My.

Diamonds, Emeralds, and Sapphires, Oh My.  Treasure Bezel Cups

Treasure Bezel Cups Three Leaves Earrings

Three Leaves Earrings Silver and Gold Earrings

Silver and Gold Earrings Make a Hidden Bail

Make a Hidden Bail Wire Links 4, 5, 6

Wire Links 4, 5, 6 Wire Links 7, 8, 9, and 10

Wire Links 7, 8, 9, and 10 Double Loop Ear Wires

Double Loop Ear Wires Balled and Paddled Head Pins

Balled and Paddled Head Pins Textured Stacked Rings

Textured Stacked Rings Cord and Bead Earrings

Cord and Bead Earrings Bali Style Adjustable Closures

Bali Style Adjustable Closures Organic Fused Silver Dust Earrings

Organic Fused Silver Dust Earrings Mobius Rings

Mobius Rings Dainty Bead and Wire Bangle with Hook Closure

Dainty Bead and Wire Bangle with Hook Closure Seed Bead and Nugget Necklace

Seed Bead and Nugget Necklace Love Locks Heart Charm

Love Locks Heart Charm Traditional Southwest Style Hook Closures

Traditional Southwest Style Hook Closures  Negative Space Earrings

Negative Space Earrings Jumbled Lacy Chain

Jumbled Lacy Chain Easy Beaded Post Hoop Earrings

Easy Beaded Post Hoop Earrings Rustic Silver Links

Rustic Silver Links Make a Soldered Paperclip Chain

Make a Soldered Paperclip Chain Make a Fused Paperclip Chain

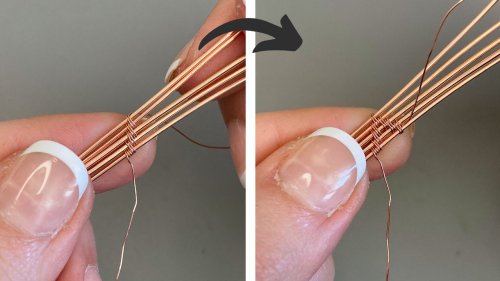

Make a Fused Paperclip Chain Make Woven Metal Strips to Use in Your Designs

Make Woven Metal Strips to Use in Your Designs Leaf Wrap Metal Rings version 1

Leaf Wrap Metal Rings version 1 Leaf Wrap Metal Rings version 2

Leaf Wrap Metal Rings version 2 Snowflake Ornaments

Snowflake Ornaments Mitten Ornament

Mitten Ornament Gnome Ornaments

Gnome Ornaments A Partridge in a Pear Tree Earrings

A Partridge in a Pear Tree Earrings Two Turtle Doves Earrings

Two Turtle Doves Earrings Three French Hens Earrings

Three French Hens Earrings Four Calling Birds Earrings

Four Calling Birds Earrings Five Golden Rings Earrings

Five Golden Rings Earrings Six Geese a Layin' Earrings

Six Geese a Layin' Earrings Seven Swans a Swimming Earrings

Seven Swans a Swimming Earrings Eight Maids a Milking earrings

Eight Maids a Milking earrings Nine Ladies Dancing Earrings

Nine Ladies Dancing Earrings Ten Lords a Leaping Earrings

Ten Lords a Leaping Earrings Eleven Pipers Piping Earrings

Eleven Pipers Piping Earrings Twelve Drummers Drumming Earrings

Twelve Drummers Drumming Earrings Make Your Own Bracelet Button Clasps

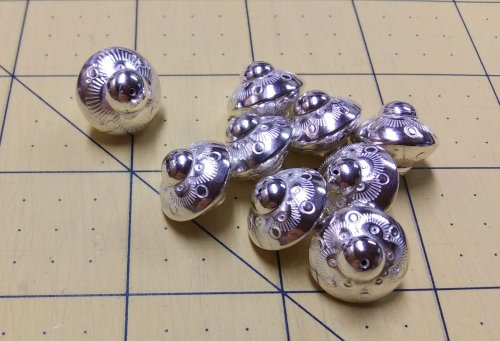

Make Your Own Bracelet Button Clasps Little Saucer Bells

Little Saucer Bells Doodads - Fun Findings

Doodads - Fun Findings No Measure Hearts, Any Size, Any Gauge

No Measure Hearts, Any Size, Any Gauge  Cascading Drops Earrings

Cascading Drops Earrings WIre Basics - Spiral Charms

WIre Basics - Spiral Charms Wire Basics - Wrapped Loops and Links

Wire Basics - Wrapped Loops and Links Wire Basics - Simple Swan Hook

Wire Basics - Simple Swan Hook Wire Crocheted Necklace

Wire Crocheted Necklace Wire Basics - Wire Garage Door Spring Link

Wire Basics - Wire Garage Door Spring Link Easy Post Hoop Earrings

Easy Post Hoop Earrings Double Wrap Wire Bangle Bracelet

Double Wrap Wire Bangle Bracelet Organic Wire Pendant

Organic Wire Pendant Coiled, Beaded Slide

Coiled, Beaded Slide Cone and Chain Earrings

Cone and Chain Earrings Embellished Sterling Cones

Embellished Sterling Cones Classic Wire Wrap Bezelled Pendant

Classic Wire Wrap Bezelled Pendant Wire Wrap a Coin

Wire Wrap a Coin Viking Knit

Viking Knit Viking Knit Bracelet

Viking Knit Bracelet Coiled Wire End Caps

Coiled Wire End Caps Bead-Wrapped Hoop Earrings

Bead-Wrapped Hoop Earrings Copper Feather Earrings

Copper Feather Earrings Soldering a Dome to a Backplate

Soldering a Dome to a Backplate  Wire Heart Pendant with Gemstone Drop

Wire Heart Pendant with Gemstone Drop Make Basic Wire Shapes for Jewelry

Make Basic Wire Shapes for Jewelry Make Simple Wire Slide Bails

Make Simple Wire Slide Bails Coiled Bead and Twisted Wire Bracelet

Coiled Bead and Twisted Wire Bracelet Wire Triangle Link

Wire Triangle Link Bali Style Focal Toggle

Bali Style Focal Toggle Silver Nuggets

Silver Nuggets Fun Shapes Fish Hook Earrings

Fun Shapes Fish Hook Earrings After the Rain Bracelets

After the Rain Bracelets Dangling Drop Earrings

Dangling Drop Earrings Dangling Chain Sticks

Dangling Chain Sticks Wire Heart Pendant with Gemstone Drop

Wire Heart Pendant with Gemstone Drop  Tropical Leaf Earrings

Tropical Leaf Earrings Basic Bezel Wire Tutorial

Basic Bezel Wire Tutorial Dog Tag Style Necklace

Dog Tag Style Necklace Lacy Washers

Lacy Washers 8-Strand Kumihimo

8-Strand Kumihimo Closed Loop Ear Wires

Closed Loop Ear Wires Simple Strip Bails from Scratch

Simple Strip Bails from Scratch Anti-tarnish Silver Cloth Bags

Anti-tarnish Silver Cloth Bags Cotter Pin Style Bail

Cotter Pin Style Bail Holiday Woodland Fairy Ornament

Holiday Woodland Fairy Ornament Happy Holly Days Wreath Ornament

Happy Holly Days Wreath Ornament Happy Holly Days Leaves and Berries

Happy Holly Days Leaves and Berries Happy Holly Days Bells Ornament

Happy Holly Days Bells Ornament  Art Deco Wire Wrapped Pendant

Art Deco Wire Wrapped Pendant Twisted Wire Jump Rings

Twisted Wire Jump Rings Two-tone Beaded Bangle

Two-tone Beaded Bangle Sweetheart Pendant

Sweetheart Pendant Waves on the Beach Earrings

Waves on the Beach Earrings Any Size Wire Hearts - Any Size, Any Gauge

Any Size Wire Hearts - Any Size, Any Gauge Just in Case Heart Pendant

Just in Case Heart Pendant Small Flower Embellishment

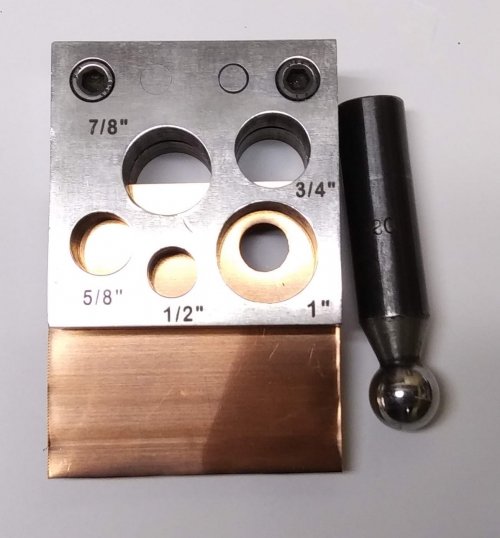

Small Flower Embellishment Making Tiny Dapped Metal Leaves

Making Tiny Dapped Metal Leaves Spinner Fidget Bangles

Spinner Fidget Bangles Small Flower Bud Embellishment

Small Flower Bud Embellishment Three Petal Bud and Layered Embellishment

Three Petal Bud and Layered Embellishment Creating a Flower Stem

Creating a Flower Stem Stamped Tube Beads

Stamped Tube Beads Water Cast Scrap Cross

Water Cast Scrap Cross Sugared Grapes Pendant

Sugared Grapes Pendant Tourist Rock Cuff Bracelet

Tourist Rock Cuff Bracelet Gemstone Chains Reimagined

Gemstone Chains Reimagined