Bezels Using Square Wire

- Category: Metalwork

- Technique(s): Cutting, Filing / Finishing, Butane Torch Techniques, Design

- Skill Level: Intermediate

Use your imagination to fill these three different size bezels made using the large Multi-Size Wrap 'N' Tap Pliers. Consider using small Multi-Size Wrap 'N' Tap Pliers or 6-Step Looping Pliers for smaller bezels. Change the gauge of the square wire to suit the size of the bezels being made. Texturing the top of the bezel wire after the piece is made will add another dimension to the piece.

Materials

16 Gauge Square Dead Soft .925 Sterling Silver Wire

H8-16SQD

- Lesson Quantity: 1.00 pieces

- Purchase Quantity: 1.00 1FT

- Price: $16.11

- Gold Club Price: $12.08

26 Gauge Dead Soft Argentium Silver Sheet - 6 Inches

H19-26SM6

- Lesson Quantity: 1.00 pieces

- Purchase Quantity: 1.00 1 Inch

- Price: $52.79

- Gold Club Price: $39.60

18 gauge 4mm jump ring

- Lesson Quantity: 1.00 pieces

- Purchase Quantity: 1.00 each

Tools

Silver Solder Paste Hard SS75 - 1/4 T.O.

SOL-822.20

- SOL-822.20

- Lesson Quantity: 1.00 pieces

- Purchase Quantity: 1.00 each

- Price: $19.95

- Gold Club Price: $14.96

Silver Solder Paste Medium SS70 - 1/4 T.O.

SOL-822.15

- SOL-822.15

- Lesson Quantity: 1.00 pieces

- Purchase Quantity: 1.00 each

- Price: $18.95

- Gold Club Price: $14.21

Silver Solder Paste Soft SS65- 1/4 T.O.

SOL-822.10

- SOL-822.10

- Lesson Quantity: 1.00 pieces

- Purchase Quantity: 1.00 each

- Price: $16.95

- Gold Club Price: $12.71

14mm Barrel Wrap N Tap Looping Pliers for Pattern Wire, Etc.

G2-79

- G2-79

- Lesson Quantity: 1.00 pieces

- Purchase Quantity: 1.00 each

- Price: $24.97

- Gold Club Price: $18.73

Xuron Flush Cutter - Pack of 1

G2-504

- G2-504

- Lesson Quantity: 1.00 pieces

- Purchase Quantity: 1.00 each

- Price: $29.95

- Gold Club Price: $22.46

4.5 Inch Flat Nose Mini Pliers

G2-88

- G2-88

- Lesson Quantity: 2.00 pieces

- Purchase Quantity: 2.00 each

- Price: $4.97

- Gold Club Price: $3.73

Multi Angle Cutting Jig

VIS-512.00

- VIS-512.00

- Lesson Quantity: 1.00 pieces

- Purchase Quantity: 1.00 each

- Price: $84.95

- Gold Club Price: $63.71

Blazer Big Buddy Turbo Torch, White

TRCH-8012

- TRCH-8012

- Lesson Quantity: 1.00 pieces

- Purchase Quantity: 1.00 each

- Price: $40.00

- Gold Club Price: $30.00

GROBET FILE - BARRETTE CUT 2, 6"

FIL-31.030

- FIL-31.030

- Lesson Quantity: 1.00 pieces

- Purchase Quantity: 1.00 each

- Price: $31.20

- Gold Club Price: $23.40

GROBET FILE - BARRETTE CUT 4, 6"

FIL-31.031

- FIL-31.031

- Lesson Quantity: 1.00 pieces

- Purchase Quantity: 1.00 each

- Price: $35.10

- Gold Club Price: $26.33

GROBET FILE - HALF ROUND RING CUT 2, 6"

FIL-31.130

- FIL-31.130

- Lesson Quantity: 1.00 pieces

- Purchase Quantity: 1.00 each

- Price: $42.30

- Gold Club Price: $31.73

Deluxe Titanium Soldering Pick, Blue Handled, 6-1/2 Inches

SPK-930.00

- SPK-930.00

- Lesson Quantity: 1.00 pieces

- Purchase Quantity: 1.00 each

- Price: $5.97

- Gold Club Price: $4.48

WireJewelry Medium Duty Insulating Fire Brick, Rated up to 2300 Degree Fahrenheit

G32-10

- G32-10

- Lesson Quantity: 1.00 pieces

- Purchase Quantity: 1.00 each

- Price: $19.95

- Gold Club Price: $14.96

5/8 Inch Double Rubber/Nylon Head Hammer - Pack of 1

G3-26

- G3-26

- Lesson Quantity: 1.00 pieces

- Purchase Quantity: 1.00 each

- Price: $4.97

- Gold Club Price: $3.73

Steel Bench Block 4x4 Inch - Pack of 1

G17-10

- G17-10

- Lesson Quantity: 2.00 pieces

- Purchase Quantity: 2.00 each

- Price: $21.95

- Gold Club Price: $16.46

French Shears - Curved Shear with Spring

SHR-531.01

- SHR-531.01

- Lesson Quantity: 1.00 pieces

- Purchase Quantity: 1.00 each

- Price: $29.97

- Gold Club Price: $22.48

Pickle Pot, 16 Ounces

CLN-584.00

- CLN-584.00

- Lesson Quantity: 1.00 pieces

- Purchase Quantity: 1.00 each

- Price: $31.95

- Gold Club Price: $23.96

Sparex Number 2 Pickling Compound

SOL-802.10

- SOL-802.10

- Lesson Quantity: 1.00 pieces

- Purchase Quantity: 1.00 each

- Price: $7.95

- Gold Club Price: $5.96

Instructions

Step 1

Read through all the directions before beginning the project.

For the smaller bezel, tightly wrap the square wire around the outer section of the Wrap 'N' Tap pliers to make as many bezel rings as needed.

Use the center section to make the medium bezel rings and the large section to make large rings.

Keep the wire from twisting while wrapping on the pliers.

Remember, bezels will not be the diameter of the barrel used.

Because wire has a spring to it when coiled, each ring will end up larger than the diameter of the barrel.

If a tighter coil is desired as well as making it easier to wrap, you may wish to anneal the wire, before coiling on the pliers.

Even though the wire is dead soft, it will become easier to work with after annealing.

For the smaller bezel, tightly wrap the square wire around the outer section of the Wrap 'N' Tap pliers to make as many bezel rings as needed.

Use the center section to make the medium bezel rings and the large section to make large rings.

Keep the wire from twisting while wrapping on the pliers.

Remember, bezels will not be the diameter of the barrel used.

Because wire has a spring to it when coiled, each ring will end up larger than the diameter of the barrel.

If a tighter coil is desired as well as making it easier to wrap, you may wish to anneal the wire, before coiling on the pliers.

Even though the wire is dead soft, it will become easier to work with after annealing.

If Multi-Size Wrap 'N' Tap Large Barrel Pliers are not available, use this method:

For a bezel the size of the smallest barrel, flush cut both ends of a piece of 16 gauge square wire to make it 1-15/16" long.

For a bezel the size of the medium barrel, flush cut both ends of a piece of 16 gauge square wire to make it 2-5/16" long.

For a bezel the size of the large barrel, flush cut both ends of a piece of 16 gauge square wire to make it 3-1/8" long.

For a bezel the size of the smallest barrel, flush cut both ends of a piece of 16 gauge square wire to make it 1-15/16" long.

For a bezel the size of the medium barrel, flush cut both ends of a piece of 16 gauge square wire to make it 2-5/16" long.

For a bezel the size of the large barrel, flush cut both ends of a piece of 16 gauge square wire to make it 3-1/8" long.

Step 2

Use the Lindstrom cutter to cut the ring coil apart.

The cut ends will not be perfectly flat.

Straighten out the wire of each ring a bit.

The cut ends will not be perfectly flat.

Straighten out the wire of each ring a bit.

Step 3

File the ends flat.

Method 1: Place a wire in the Miter-Cutting Vise and Jig with a flat side of the wire pushed securely against the flat fence between the 90 degree jaws.

Very little metal needs to be removed after cutting with the Lindstrom shears or flush cutting so only the part that needs to be filed off should be protruding from the tool.

File the end of the wire flush with the Jig to achieve a perfect 90 degree angle to the wire length.

Repeat with the other end of the wire.

Method 1: Place a wire in the Miter-Cutting Vise and Jig with a flat side of the wire pushed securely against the flat fence between the 90 degree jaws.

Very little metal needs to be removed after cutting with the Lindstrom shears or flush cutting so only the part that needs to be filed off should be protruding from the tool.

File the end of the wire flush with the Jig to achieve a perfect 90 degree angle to the wire length.

Repeat with the other end of the wire.

Method 2: Tightly grasp one end of a wire between the jaw tips of a flat nose pliers.

The wire length should be parallel to the tips of the pliers and only the part that needs to be filed off should be outside the side edge of the tips of the pliers, as shown in the photo.

File the wire end off to make it smooth and flat.

Repeat with the other end of the wire.

The wire length should be parallel to the tips of the pliers and only the part that needs to be filed off should be outside the side edge of the tips of the pliers, as shown in the photo.

File the wire end off to make it smooth and flat.

Repeat with the other end of the wire.

Step 4

Round each straight wire a bit and bring the ends evenly together in a straight line, making a "D Ring" as shown.

Make sure that there is no space between the wire ends.

Do not worry that the rings are not perfectly round.

Also, do not worry if the square wire ring is not quite flat, so long as the ends match up.

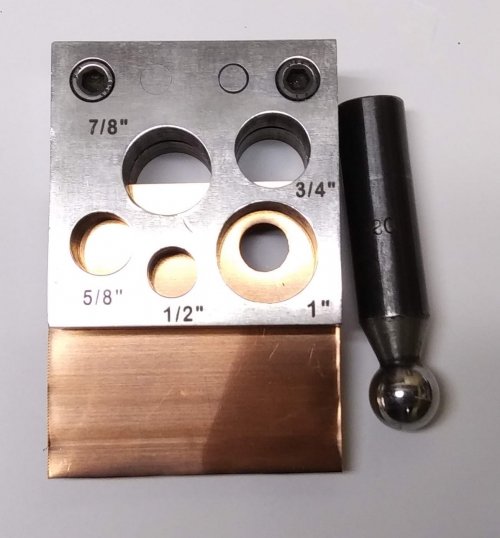

Hint: If the ends of the ring just will not meet, place the ring in a depression in a swage block that has a smaller curve than the ring.

Slide a non-marring tool like a barrel of a Sharpie marker or a dowel through the ring.

Push the marker or dowel down evenly on both side of the ring.

This will help bring the ends of the ring together.

Make sure that there is no space between the wire ends.

Do not worry that the rings are not perfectly round.

Also, do not worry if the square wire ring is not quite flat, so long as the ends match up.

Hint: If the ends of the ring just will not meet, place the ring in a depression in a swage block that has a smaller curve than the ring.

Slide a non-marring tool like a barrel of a Sharpie marker or a dowel through the ring.

Push the marker or dowel down evenly on both side of the ring.

This will help bring the ends of the ring together.

Step 5

Place the ring on a solder brick.

If doing multiple ring, spread them out on the solder brick.

Place a small amount of hard paste solder (medium past solder if working with Argentium) under the join.

The first photo shows how much solder to use.

Remember, too much solder equals more clean-up later.

Use a butane torch to evenly heat each ring, moving the torch around the outside of the ring until the solder flows up through the join.

Immediately remove the torch.

Allow to cool for a bit before quenching.

If doing multiple ring, spread them out on the solder brick.

Place a small amount of hard paste solder (medium past solder if working with Argentium) under the join.

The first photo shows how much solder to use.

Remember, too much solder equals more clean-up later.

Use a butane torch to evenly heat each ring, moving the torch around the outside of the ring until the solder flows up through the join.

Immediately remove the torch.

Allow to cool for a bit before quenching.

Step 6

Use 320, 400, and then 600 grit sandpaper or sanding pads to clean and refine the solder join on the inside of each ring.

The other three sides will be cleaned up in later steps during construction.

The other three sides will be cleaned up in later steps during construction.

Step 7

Slide a ring down onto a ring mandrel.

For rings larger than a ring mandrel can accommodate, a hoop mandrel can be used-third photo.

Gently press the ring down the length of the mandrel.

If the join breaks during this step or the next, straighten the wire and file the ends again.

Reform and solder the ring again.

For rings larger than a ring mandrel can accommodate, a hoop mandrel can be used-third photo.

Gently press the ring down the length of the mandrel.

If the join breaks during this step or the next, straighten the wire and file the ends again.

Reform and solder the ring again.

Step 8

Gently tap the ring with a rubber, plastic or rawhide mallet to make it round.

Also, periodically remove the ring and turn it over on the mandrel.

Also, periodically remove the ring and turn it over on the mandrel.

Step 9

Remove the ring from the mandrel and place it on a bench block.

Use a rubber, plastic or rawhide mallet to flatten the ring, making sure the wire ring is as flat as possible.

Place the ring in the center of a bench block.

Place another bench block on top of the ring, catty (or kitty) corner.

Doing this makes it easier to pick the top block up with the fingers of two hands.

Pick the block up a half inch or so above the lower block and evenly, forcefully, and quickly push the top block down onto the ring.

This should "square up" the ring wire.

If needed, anneal the ring, flip it over on the bench block and repeat the process.

Use a rubber, plastic or rawhide mallet to flatten the ring, making sure the wire ring is as flat as possible.

Place the ring in the center of a bench block.

Place another bench block on top of the ring, catty (or kitty) corner.

Doing this makes it easier to pick the top block up with the fingers of two hands.

Pick the block up a half inch or so above the lower block and evenly, forcefully, and quickly push the top block down onto the ring.

This should "square up" the ring wire.

If needed, anneal the ring, flip it over on the bench block and repeat the process.

Step 10

Place a piece sandpaper on a bench block or other flat surface with no give.

Using two or three fingers to hold the ring down on the sandpaper, use a figure 8 motion to sand the back perfectly flat.

This will be the side that faces the backplate.

Using two or three fingers to hold the ring down on the sandpaper, use a figure 8 motion to sand the back perfectly flat.

This will be the side that faces the backplate.

Step 11

Place the ring on the 26 gauge sheet metal to be used as the bezel backplate.

Trace around the ring with an ultra fine point Sharpie marker.

Trace around the ring with an ultra fine point Sharpie marker.

Step 12

Leaving room around the marked circle, use a French shears to cut a section of sheet metal.

This piece will be the bezel backing.

This piece will be the bezel backing.

Step 13

Use a metal content and/or a Makers Mark stamp to mark the back of the sheet metal where the eventual top of the piece will be.

This will show through to the other side of the metal because the sheet is so thin.

If the inside of the bezel will show in the project it is being used for, skip this step.

This will show through to the other side of the metal because the sheet is so thin.

If the inside of the bezel will show in the project it is being used for, skip this step.

Step 14

The sheet metal may need to be annealed and pickled before using the process described in Step 8 to flatten it.

Hint: Squeeky clean metal equals successful solder joins.

Every time a torch is used to fuse, solder or ball wire ends or work on sheet metal, fire scale develops.

It is necessary to pickle these pieces to remove the fire scale so each succeeding solder join is successful.

If pickling is not necessary, rubbing alcohol can be used to remove finger oils, etc., from pieces before soldering.

Hint: Squeeky clean metal equals successful solder joins.

Every time a torch is used to fuse, solder or ball wire ends or work on sheet metal, fire scale develops.

It is necessary to pickle these pieces to remove the fire scale so each succeeding solder join is successful.

If pickling is not necessary, rubbing alcohol can be used to remove finger oils, etc., from pieces before soldering.

Step 15

Place the backing on a solder brick with the stamp facing down.

Place medium paste solder around the underside of a ring (the side sanded with 320 grit sandpaper).

Press the ring on the backing, solder side down, making sure that the seam in the ring is directly at the top of the piece, above the metal content stamp impression, which shows through from the other side.

If any solder squishes inside the ring, remove it with a q-tip while holding the bezel ring in place.

Place medium paste solder around the underside of a ring (the side sanded with 320 grit sandpaper).

Press the ring on the backing, solder side down, making sure that the seam in the ring is directly at the top of the piece, above the metal content stamp impression, which shows through from the other side.

If any solder squishes inside the ring, remove it with a q-tip while holding the bezel ring in place.

Step 16

Use the butane torch to evenly heat the ring and backing, moving the torch around the ring, the thickest part of the piece, and occasionally over the middle, until the solder flows.

The object is to get the solder to flow from under the ring to the outside, not the inside, of the ring.

Immediately remove the torch.

Let cool before quenching.

The object is to get the solder to flow from under the ring to the outside, not the inside, of the ring.

Immediately remove the torch.

Let cool before quenching.

Step 17

Pickle the piece to remove any fire scale. Rinse and dry the piece.

Step 18

Use French shears to cut the excess backing away from the ring.

Be careful to not remove any of the square bezel wire.

Be careful to not remove any of the square bezel wire.

Step 19

File and then refine the edges with sandpaper or sanding pads until the join between the ring and the backplate does not show.

It may be helpful to raise the piece on a block for this process.

Use a sanding stick to smooth down the areas inside the bezel where solder may have flowed.

It may be helpful to raise the piece on a block for this process.

Use a sanding stick to smooth down the areas inside the bezel where solder may have flowed.

Step 20

Place the bezel right side down on a piece of 400 grit sandpaper.

Use a figure 8 motion to sand the top of the bezel ring perfectly flat.

Repeat using the 600 and then the 1200 grit sandpaper.

Use a figure 8 motion to sand the top of the bezel ring perfectly flat.

Repeat using the 600 and then the 1200 grit sandpaper.

Step 21

Repeat Step 19 on the back of the bezel.

Step 22

Close an 18 gauge 3.5mm ID jump ring (small barrel bezel) or a 4mm ID jump ring (medium and large barrel bezel) so there is no space between the two ends.

This part is optional. If you are comfortable with soldering, when you solder the ring to the bezel in Step 28 the solder from that step should fill the seam, securing the ends together as well as securing the ring to the bezel.

If not, place a small amount of medium solder under the join.

The photo shows how much solder to use.

Flip the ring over so the solder is under the seam.

Use the butane torch to evenly heat the ring, moving the torch around the outside of the ring until the solder flows through the join.

Immediately remove the torch.

If not, place a small amount of medium solder under the join.

The photo shows how much solder to use.

Flip the ring over so the solder is under the seam.

Use the butane torch to evenly heat the ring, moving the torch around the outside of the ring until the solder flows through the join.

Immediately remove the torch.

Step 23

Pickle, rinse and dry the jump ring.

Step 24

File a very small section flat at the top of the bezel where the bezel and the ring will meet.

The top of the bezel is where the solder join in the bezel ring is.

The jump ring is not as thick as the bezel so only file the necessary area.

The filed section should be at a 90 degree angle to the backplate.

A Miter-Cutting Vise and Jig is a VERY useful tool for this.

The top of the bezel is where the solder join in the bezel ring is.

The jump ring is not as thick as the bezel so only file the necessary area.

The filed section should be at a 90 degree angle to the backplate.

A Miter-Cutting Vise and Jig is a VERY useful tool for this.

Step 25

File a very small section of the closed ring at the join to correspond to the bezel.

This needs to be done so there is more than just a very tiny connection between the two pieces being soldered together, thus creating a stronger join.

The filed section should be perfectly flat.

Again, using the Miter-Cutting Vise and Jig makes the filed section perfect.

This needs to be done so there is more than just a very tiny connection between the two pieces being soldered together, thus creating a stronger join.

The filed section should be perfectly flat.

Again, using the Miter-Cutting Vise and Jig makes the filed section perfect.

Step 26

Place a small amount of easy paste solder on the flat portion of the bezel where the ring will be joined to it.

Place the ring on the solder brick.

Slide the flattened section of the ring towards the flattened section of the bezel with the solder.

Push the two pieces together.

Place the ring on the solder brick.

Slide the flattened section of the ring towards the flattened section of the bezel with the solder.

Push the two pieces together.

Step 27

Use the butane torch to evenly heat the bezel unit, moving the torch around the outside of the bezel, the thickest part of the piece, and occasionally over the middle.

Try not to heat the ring too much as it is a much smaller piece and could melt or with too much heat.

When the solder flows, immediately remove the torch.

Allow to cool before quenching.

Try not to heat the ring too much as it is a much smaller piece and could melt or with too much heat.

When the solder flows, immediately remove the torch.

Allow to cool before quenching.

Step 28

Pickle the finished bezel to remove fire scale. Rinse and dry.

Step 29

Inspect the piece and make any refinements needed with 600 and then 1200 grit sandpaper.

Step 30

Tumble the bezel for several hours. If the ring is still attached to the bezel when it is removed from the tumbler, it is permanent.

The old solder should be filed off.

Then repeat Steps 22 through 26 again.

It is easiest to use a new ring as removing the old solder from a tiny ring is not easy.

The old solder should be filed off.

Then repeat Steps 22 through 26 again.

It is easiest to use a new ring as removing the old solder from a tiny ring is not easy.

Step 31:

Ideas for Use

Seal a photo, print, dried flower petals, etc., under resin.

Research copyright free astrological star sign charts.

Solder small bits of balled wire to the bezel back to mimic your astrological sign.

Solder small bits of balled wire to the bezel back to mimic your astrological sign.

Put some glue in the bottom and sprinkle on gemstone chips for a "druzy" look-alike.

Change the shape of the backing, add two connectors, put a domed disc inside the bezel, and add a few embellishments, and the bezel becomes a link.

Beaded Briolette Pendant

Beaded Briolette Pendant

Snail Trail Spiral Earrings

Snail Trail Spiral Earrings

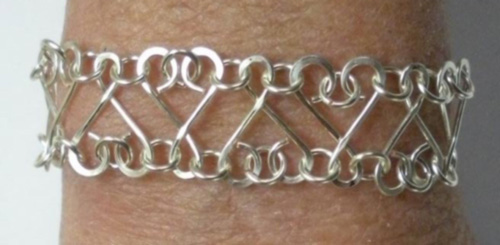

Heart Link Bracelet and Earrings

Heart Link Bracelet and Earrings

Crazy Hoop Earrings

Crazy Hoop Earrings

Double Delight Jade Bracelet

Double Delight Jade Bracelet

Swagged Pearl Pendant

Swagged Pearl Pendant

Heart Earrings with Drops

Heart Earrings with Drops

Scarab Bracelet

Scarab Bracelet

Birthstone Heart Pendant

Birthstone Heart Pendant

Pearl of the Sea Woven Pendant

Pearl of the Sea Woven Pendant

Bead Charm

Bead Charm

Coiled Rosette Link

Coiled Rosette Link

Wire Jewelry Component and Swan Hook

Wire Jewelry Component and Swan Hook

Leaf Bail

Leaf Bail

Component Templates with Heart Earrings and Pendant

Component Templates with Heart Earrings and Pendant

Ring Pendant

Ring Pendant

Calla Lily Earrings

Calla Lily Earrings

Birdhouse Pendant

Birdhouse Pendant

Clamshell Earrings and Pendant

Clamshell Earrings and Pendant

Bracelet Component

Bracelet Component

Teardrop Earrings and Pendant

Teardrop Earrings and Pendant

Tab Style Pendant

Tab Style Pendant

Coiled End Caps

Coiled End Caps

Freeform Pendant

Freeform Pendant

French Hook Ear Wires

French Hook Ear Wires

Necklace Component

Necklace Component

Triangle Shield Earrings, Pendant and Bail

Triangle Shield Earrings, Pendant and Bail

How to Make a Wire Coil and Bead

How to Make a Wire Coil and Bead

Egyptian Coil Bracelet

Egyptian Coil Bracelet

Focal Bead Egyptian Coiled Bracelet

Focal Bead Egyptian Coiled Bracelet

Sweetheart Round Cabochon Pendant

Sweetheart Round Cabochon Pendant

Making Cobblestone Cabochons

Making Cobblestone Cabochons

Cupcake Wrapper Earrings

Cupcake Wrapper Earrings

How to Make Metal Washers

How to Make Metal Washers

Baseball Skin Keychain

Baseball Skin Keychain

Pat's Silver Domed Earrings

Pat's Silver Domed Earrings

Blaze Your Own Path Pendant

Blaze Your Own Path Pendant

Semi Snap-on Bail

Semi Snap-on Bail

Interlocking Faux Twist Wire Bracelet

Interlocking Faux Twist Wire Bracelet

Fold Formed Cuff With Faux Roman Glass or Coin Cabochon

Fold Formed Cuff With Faux Roman Glass or Coin Cabochon

Steampunk Style Leaf Earrings

Steampunk Style Leaf Earrings

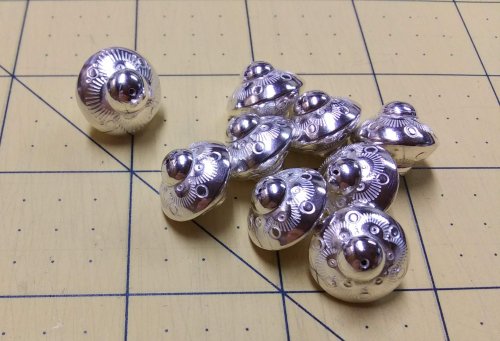

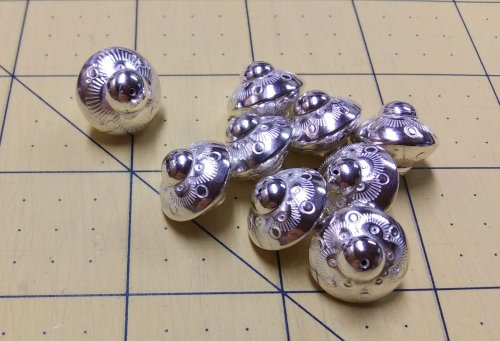

Stamped Saucer Beads

Stamped Saucer Beads

Kat's Wire Hoop Earrings

Kat's Wire Hoop Earrings

Simple Bail on a Coin Pendant

Simple Bail on a Coin Pendant

Wire Bangles

Wire Bangles

Rolling Mill - or not - Cuff Bracelet

Rolling Mill - or not - Cuff Bracelet

Jen's Chain

Jen's Chain

Making Neckwires

Making Neckwires

Silver Scrap Wire Focals to Embellish

Silver Scrap Wire Focals to Embellish

Splash Ring

Splash Ring

Cobblestone Cab Earrings

Cobblestone Cab Earrings

Multi Gemstone Necklace

Multi Gemstone Necklace

Southwest Style Pendant

Southwest Style Pendant

Mixed Metal Sampler Bracelet 1

Mixed Metal Sampler Bracelet 1

Mixed Metal Sampler Bracelet 2

Mixed Metal Sampler Bracelet 2

Mixed Metal Sampler Bracelet 3

Mixed Metal Sampler Bracelet 3

Mixed Metal Sampler Bracelet 4 - Words Matter

Mixed Metal Sampler Bracelet 4 - Words Matter

Mixed Metal Sampler Bracelet 5 - River Walk

Mixed Metal Sampler Bracelet 5 - River Walk

Mixed Metal Sampler Bracelet 6 - A Little Bling

Mixed Metal Sampler Bracelet 6 - A Little Bling

Mixed Metal Sampler Bracelets Series PUTTING IT ALL TOGETHER

Mixed Metal Sampler Bracelets Series PUTTING IT ALL TOGETHER

Mixed Metal Sampler Bracelet 7 - Steampunk Space Oddity

Mixed Metal Sampler Bracelet 7 - Steampunk Space Oddity

Mixed Metal Sampler Bracelet 8 - Fun Shapes

Mixed Metal Sampler Bracelet 8 - Fun Shapes

Jump Ring Fringe Bracelet

Jump Ring Fringe Bracelet

Easy Artisan Earrings

Easy Artisan Earrings

Making Chain with Wubbers and Wire

Making Chain with Wubbers and Wire

Heirloom Buttons and Beads Bracelet

Heirloom Buttons and Beads Bracelet

Tiny Silver Charms part 1

Tiny Silver Charms part 1

Argentium Silver Scrap Chain

Argentium Silver Scrap Chain

Sterling Lake Stone Pendant with Twisted Wire

Sterling Lake Stone Pendant with Twisted Wire

Smashing Drop Earrings

Smashing Drop Earrings

Argentium Silver Scrap Nugget Cuff

Argentium Silver Scrap Nugget Cuff

Finish Them Your Way Earrings

Finish Them Your Way Earrings

Paddle Fringe Earrings

Paddle Fringe Earrings

Seed Bead Earrings

Seed Bead Earrings

Bracelet Links 1, 2,3

Bracelet Links 1, 2,3

Stamped Saucer Beads

Stamped Saucer Beads

Chaos Scrap Wrap Jewelry

Chaos Scrap Wrap Jewelry

Maple Leaf Earrings

Maple Leaf Earrings

Child's Bracelet That Grows with Them

Child's Bracelet That Grows with Them

Mike's Surpirise Claire's Ripple Pendant

Mike's Surpirise Claire's Ripple Pendant

Angel Ornament

Angel Ornament

Diamonds, Emeralds, and Sapphires, Oh My.

Diamonds, Emeralds, and Sapphires, Oh My.

Treasure Bezel Cups

Treasure Bezel Cups

Three Leaves Earrings

Three Leaves Earrings

Silver and Gold Earrings

Silver and Gold Earrings

Make a Hidden Bail

Make a Hidden Bail

Wire Links 4, 5, 6

Wire Links 4, 5, 6

Wire Links 7, 8, 9, and 10

Wire Links 7, 8, 9, and 10

Double Loop Ear Wires

Double Loop Ear Wires

Balled and Paddled Head Pins

Balled and Paddled Head Pins

Textured Stacked Rings

Textured Stacked Rings

Cord and Bead Earrings

Cord and Bead Earrings

Bali Style Adjustable Closures

Bali Style Adjustable Closures

Organic Fused Silver Dust Earrings

Organic Fused Silver Dust Earrings

Mobius Rings

Mobius Rings

Dainty Bead and Wire Bangle with Hook Closure

Dainty Bead and Wire Bangle with Hook Closure

Seed Bead and Nugget Necklace

Seed Bead and Nugget Necklace

Love Locks Heart Charm

Love Locks Heart Charm

Traditional Southwest Style Hook Closures

Traditional Southwest Style Hook Closures

Negative Space Earrings

Negative Space Earrings

Jumbled Lacy Chain

Jumbled Lacy Chain

Easy Beaded Post Hoop Earrings

Easy Beaded Post Hoop Earrings

Rustic Silver Links

Rustic Silver Links

Make a Soldered Paperclip Chain

Make a Soldered Paperclip Chain

Make a Fused Paperclip Chain

Make a Fused Paperclip Chain

Make Woven Metal Strips to Use in Your Designs

Make Woven Metal Strips to Use in Your Designs

Leaf Wrap Metal Rings version 1

Leaf Wrap Metal Rings version 1

Leaf Wrap Metal Rings version 2

Leaf Wrap Metal Rings version 2

Snowflake Ornaments

Snowflake Ornaments

Mitten Ornament

Mitten Ornament

Gnome Ornaments

Gnome Ornaments

A Partridge in a Pear Tree Earrings

A Partridge in a Pear Tree Earrings

Two Turtle Doves Earrings

Two Turtle Doves Earrings

Three French Hens Earrings

Three French Hens Earrings

Four Calling Birds Earrings

Four Calling Birds Earrings

Five Golden Rings Earrings

Five Golden Rings Earrings

Six Geese a Layin' Earrings

Six Geese a Layin' Earrings

Seven Swans a Swimming Earrings

Seven Swans a Swimming Earrings

Eight Maids a Milking earrings

Eight Maids a Milking earrings

Nine Ladies Dancing Earrings

Nine Ladies Dancing Earrings

Ten Lords a Leaping Earrings

Ten Lords a Leaping Earrings

Eleven Pipers Piping Earrings

Eleven Pipers Piping Earrings

Twelve Drummers Drumming Earrings

Twelve Drummers Drumming Earrings

Make Your Own Bracelet Button Clasps

Make Your Own Bracelet Button Clasps

Little Saucer Bells

Little Saucer Bells

Doodads - Fun Findings

Doodads - Fun Findings

No Measure Hearts, Any Size, Any Gauge

No Measure Hearts, Any Size, Any Gauge

Cascading Drops Earrings

Cascading Drops Earrings

WIre Basics - Spiral Charms

WIre Basics - Spiral Charms

Wire Basics - Wrapped Loops and Links

Wire Basics - Wrapped Loops and Links

Wire Basics - Simple Swan Hook

Wire Basics - Simple Swan Hook

Wire Crocheted Necklace

Wire Crocheted Necklace

Wire Basics - Wire Garage Door Spring Link

Wire Basics - Wire Garage Door Spring Link

Easy Post Hoop Earrings

Easy Post Hoop Earrings

Double Wrap Wire Bangle Bracelet

Double Wrap Wire Bangle Bracelet

Organic Wire Pendant

Organic Wire Pendant

Coiled, Beaded Slide

Coiled, Beaded Slide

Cone and Chain Earrings

Cone and Chain Earrings

Embellished Sterling Cones

Embellished Sterling Cones

Classic Wire Wrap Bezelled Pendant

Classic Wire Wrap Bezelled Pendant

Wire Wrap a Coin

Wire Wrap a Coin

Viking Knit

Viking Knit

Viking Knit Bracelet

Viking Knit Bracelet

Bead-Wrapped Hoop Earrings

Bead-Wrapped Hoop Earrings

Copper Feather Earrings

Copper Feather Earrings

Soldering a Dome to a Backplate

Soldering a Dome to a Backplate

Wire Heart Pendant with Gemstone Drop

Wire Heart Pendant with Gemstone Drop

Make Basic Wire Shapes for Jewelry

Make Basic Wire Shapes for Jewelry

Make Simple Wire Slide Bails

Make Simple Wire Slide Bails

Coiled Bead and Twisted Wire Bracelet

Coiled Bead and Twisted Wire Bracelet

Wire Triangle Link

Wire Triangle Link

Bali Style Focal Toggle

Bali Style Focal Toggle

Silver Nuggets

Silver Nuggets

Fun Shapes Fish Hook Earrings

Fun Shapes Fish Hook Earrings

After the Rain Bracelets

After the Rain Bracelets

Dangling Drop Earrings

Dangling Drop Earrings

Dangling Chain Sticks

Dangling Chain Sticks

Wire Heart Pendant with Gemstone Drop

Wire Heart Pendant with Gemstone Drop

Tropical Leaf Earrings

Tropical Leaf Earrings

Basic Bezel Wire Tutorial

Basic Bezel Wire Tutorial

Dog Tag Style Necklace

Dog Tag Style Necklace

Lacy Washers

Lacy Washers

8-Strand Kumihimo

8-Strand Kumihimo

Closed Loop Ear Wires

Closed Loop Ear Wires

Simple Strip Bails from Scratch

Simple Strip Bails from Scratch

Anti-tarnish Silver Cloth Bags

Anti-tarnish Silver Cloth Bags

Cotter Pin Style Bail

Cotter Pin Style Bail

Holiday Woodland Fairy Ornament

Holiday Woodland Fairy Ornament

Happy Holly Days Wreath Ornament

Happy Holly Days Wreath Ornament

Happy Holly Days Leaves and Berries

Happy Holly Days Leaves and Berries

Happy Holly Days Bells Ornament

Happy Holly Days Bells Ornament

Art Deco Wire Wrapped Pendant

Art Deco Wire Wrapped Pendant

Twisted Wire Jump Rings

Twisted Wire Jump Rings

Two-tone Beaded Bangle

Two-tone Beaded Bangle

Sweetheart Pendant

Sweetheart Pendant

Waves on the Beach Earrings

Waves on the Beach Earrings

Any Size Wire Hearts - Any Size, Any Gauge

Any Size Wire Hearts - Any Size, Any Gauge

Just in Case Heart Pendant

Just in Case Heart Pendant

Small Flower Embellishment

Small Flower Embellishment

Making Tiny Dapped Metal Leaves

Making Tiny Dapped Metal Leaves

Spinner Fidget Bangles

Spinner Fidget Bangles

Small Flower Bud Embellishment

Small Flower Bud Embellishment

Three Petal Bud and Layered Embellishment

Three Petal Bud and Layered Embellishment

Creating a Flower Stem

Creating a Flower Stem

Stamped Tube Beads

Stamped Tube Beads

Water Cast Scrap Cross

Water Cast Scrap Cross

Sugared Grapes Pendant

Sugared Grapes Pendant

Tourist Rock Cuff Bracelet

Tourist Rock Cuff Bracelet

Gemstone Chains Reimagined

Gemstone Chains Reimagined

Checkerboard Faceted Earrings

Checkerboard Faceted Earrings

Foxtail Chain aka Loop-in-Loop

Foxtail Chain aka Loop-in-Loop

Handmade Chunky Chain

Handmade Chunky Chain

Capture a Summer Memory

Capture a Summer Memory

Stone Key Fob

Stone Key Fob

Sprinkles Link

Sprinkles Link

Ball Chain Embellishments

Ball Chain Embellishments

Handmade Ornament Hooks

Handmade Ornament Hooks

Coin Focal

Coin Focal

Branching Out

Branching Out

Broken AKA Bits and Pieces Dish Jewelry

Broken AKA Bits and Pieces Dish Jewelry

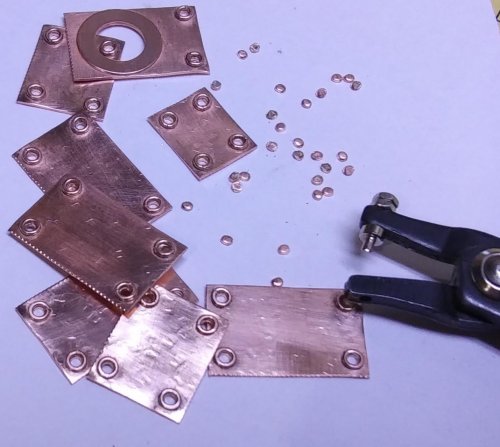

Easy No Solder Hinges

Easy No Solder Hinges

Small Embellished Classic Cross

Small Embellished Classic Cross

Closure Focal Necklace

Closure Focal Necklace

Classic Cameo Pendant

Classic Cameo Pendant

Bali Style Earrings

Bali Style Earrings

Combine Druzy With Straw and Water Cast Components

Combine Druzy With Straw and Water Cast Components

Feathers and Leaves Earring Remodel

Feathers and Leaves Earring Remodel

Five Year Bracelet

Five Year Bracelet

Designer Stick Earrings Remodel

Designer Stick Earrings Remodel

Hammered Luxury

Hammered Luxury

Recycled Black Pearl Earrings

Recycled Black Pearl Earrings

Disc Cutter Earrings Remodel

Disc Cutter Earrings Remodel

Show Your Colors Bracelet

Show Your Colors Bracelet

CZ Explosion Necklace

CZ Explosion Necklace

Domed Stud with Drop Loop

Domed Stud with Drop Loop

Gemstone Stud Earrings With Hanging Loop

Gemstone Stud Earrings With Hanging Loop

Split Bead Earrings

Split Bead Earrings

Ripple Bracelet

Ripple Bracelet

Double Foxtail Chain

Double Foxtail Chain

Stretch Bracelets

Stretch Bracelets

Copper Feather Earrings Remodel Into Cuff

Copper Feather Earrings Remodel Into Cuff

Summer Fun Necklace

Summer Fun Necklace

Reunion Key Fobs

Reunion Key Fobs

Gnome Ornaments

Gnome Ornaments

Happy Holly Days Ornament

Happy Holly Days Ornament