Soldering 101

Soldering is the most common technique for joining two or more metals together. In the soldering process, two elements are used: heat and solder. A solder is a metal alloy that has a lower melting point than the metals do that are to be joined together. When the heat from a soldering torch comes into contact with the solder and metals, the solder will melt before the metals do, causing the melted solder to flow and connect the separate pieces together.

Solders are categorized into three types: hard, medium, and easy (soft).

These categories refer to their melting points.

Soft solders melt at lower temperatures than medium and hard solders.

Hard solders, on the other hand, are typically used for jewelry making and working with precious metals.

If a piece needs to be soldered more than once, start with a hard solder, then move to a medium or soft solder.

This prevents the first solder joint from remelting.

These categories refer to their melting points.

Soft solders melt at lower temperatures than medium and hard solders.

Hard solders, on the other hand, are typically used for jewelry making and working with precious metals.

If a piece needs to be soldered more than once, start with a hard solder, then move to a medium or soft solder.

This prevents the first solder joint from remelting.

Recommended Materials

Solder

Flux

Flux brush

Tweezers

Torch

Soldering Block

Safety glasses/eye protection

Solder

Flux

Flux brush

Tweezers

Torch

Soldering Block

Safety glasses/eye protection

Steps in Soldering

1. Fitting

2. Cleaning

3. Fluxing

4. Solder Placement

5. Heating

1. Fitting

2. Cleaning

3. Fluxing

4. Solder Placement

5. Heating

Pro Tip: It is important to take safety precautions when soldering. Wear protective clothing, eye protection, make sure the area is well ventilated, and don't touch the tip or element of a soldering iron. The three major hazards of soldering are heat, fumes, and the lead content of the solder. When possible, substitute lead free solder for leaded solder.

Just what the doctor ordered!

This article will now go in depth about the 5 steps of soldering.

This article will now go in depth about the 5 steps of soldering.

Step 1: Fitting

Soldering gets challenging without a fitted join.

A fitted join means a smooth, built-in connection point between metal pieces.

Edges must match perfectly for a secure, lasting bond. Filing may be needed.

Ensure surfaces are free of dents, warping, or kinks.

For butt joins (flat edges), bevel the surfaces so metal overlaps.

This creates a strong joint.

Soldering gets challenging without a fitted join.

A fitted join means a smooth, built-in connection point between metal pieces.

Edges must match perfectly for a secure, lasting bond. Filing may be needed.

Ensure surfaces are free of dents, warping, or kinks.

For butt joins (flat edges), bevel the surfaces so metal overlaps.

This creates a strong joint.

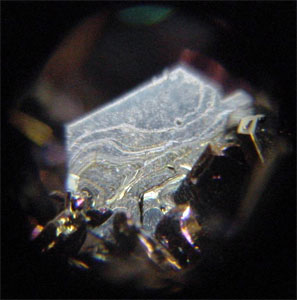

Step 2. Cleaning

Metals must be clean and free of dirt, grease, oil, and fingerprints.

Solder won't flow on unclean surfaces.

Cleaning options: pickling or sanding.

Pickling, a chemical process, works best. You'll need pickle, a pickle pot, tongs, and tweezers.

Pickle is an acidic solution in liquid or powder form. Use an old coffee pot on a hot plate or small crock pot.

Once designated as a pickle pot, never use it for cooking again.

After pickling, wash metals in water with baking soda. Use copper tongs to avoid contaminating the solution.

Dry thoroughly.

Metals must be clean and free of dirt, grease, oil, and fingerprints.

Solder won't flow on unclean surfaces.

Cleaning options: pickling or sanding.

Pickling, a chemical process, works best. You'll need pickle, a pickle pot, tongs, and tweezers.

Pickle is an acidic solution in liquid or powder form. Use an old coffee pot on a hot plate or small crock pot.

Once designated as a pickle pot, never use it for cooking again.

After pickling, wash metals in water with baking soda. Use copper tongs to avoid contaminating the solution.

Dry thoroughly.

A wet pumice stone and bristle brush or a clean piece of emery paper will also work for cleaning.

Use a clean pair of tweezers to manage the metals with after they have been cleaned.

Use a clean pair of tweezers to manage the metals with after they have been cleaned.

Step 3. Fluxing

All areas to be soldered need to be covered with flux (unless using paste solder).

Each piece of solder should also be fluxed.

Soldering flux helps dissolve and prevent oxidation of the base metal.

It also acts as a wetting agent allowing easier spreading of the solder around the join.

There are many soldering fluxes on the market available for use.

All areas to be soldered need to be covered with flux (unless using paste solder).

Each piece of solder should also be fluxed.

Soldering flux helps dissolve and prevent oxidation of the base metal.

It also acts as a wetting agent allowing easier spreading of the solder around the join.

There are many soldering fluxes on the market available for use.

Step 4. Solder Placement

Prepare a few solder snippets called pallions.

Use tweezers or a flux-moistened brush tip to place the pallion on the join.

Avoid extra pallions. They're hard to melt off and cause blemishes.

File away any excess solder that flows off.

Prepare a few solder snippets called pallions.

Use tweezers or a flux-moistened brush tip to place the pallion on the join.

Avoid extra pallions. They're hard to melt off and cause blemishes.

File away any excess solder that flows off.

Step 5. Heating

Use a torch to preheat the entire metal area evenly.

Do this carefully and quickly for good solder flow.

Heating only the solder first makes it melt into a ball that won't enter the join.

Equally heat the two or more pieces that are to be connected together.

Preheat until the piece begins to glow.

Solder will then flow and fill the seam.

Work in soft light to better see the glow.

Melted solder flows toward the hottest spot.

Move the torch to direct it as desired.

Use a torch to preheat the entire metal area evenly.

Do this carefully and quickly for good solder flow.

Heating only the solder first makes it melt into a ball that won't enter the join.

Equally heat the two or more pieces that are to be connected together.

Preheat until the piece begins to glow.

Solder will then flow and fill the seam.

Work in soft light to better see the glow.

Melted solder flows toward the hottest spot.

Move the torch to direct it as desired.

After the solder has melted to your satisfaction, cool, and place the piece in a warm pickle bath to remove oxidation.

It can also be boiled to increase the cleaning time.

It can also be boiled to increase the cleaning time.

Materials

Entire Metalworking 101 Beginner DVD Series

DVD-METALBEGset

- Lesson Quantity: 1.00 pieces

- Purchase Quantity: 1.00 each

- Price: $199.75

- Gold Club Price: $149.81

Free Introduction to Metalworking Instructional DVD

free_metalworking_dvd

- Lesson Quantity: 1.00 pieces

- Purchase Quantity: 1.00 each

- Price: $34.95

- Gold Club Price: $26.21

Sheet

Tools

Basic Soldering Kit

G15-4

- G15-4

- Lesson Quantity: 1.00 pieces

- Purchase Quantity: 1.00 each

- Price: $58.95

- Gold Club Price: $44.21

Deluxe Soldering Kit

G15-5

- G15-5

- Lesson Quantity: 1.00 pieces

- Purchase Quantity: 1.00 each

- Price: $116.97

- Gold Club Price: $87.73

Safety Glasses

G21-1

- G21-1

- Lesson Quantity: 1.00 pieces

- Purchase Quantity: 1.00 pieces

- Price: $2.97

- Gold Club Price: $2.23

- Category: Metalwork

- Technique(s): Butane Torch Techniques, Tools, General Education

About Jewelry Chain- About Ball Chain

About Jewelry Chain- About Ball Chain

About Jewelry Chain- Snake Chain and Omega Chain

About Jewelry Chain- Snake Chain and Omega Chain

About Jewelry Chain- Bar Chain and Peanut Chain

About Jewelry Chain- Bar Chain and Peanut Chain

About Jewelry Chain - Cable Chain and Rolo Chain

About Jewelry Chain - Cable Chain and Rolo Chain

About Jewelry Chain- Curb Chain and Gourmette Chain

About Jewelry Chain- Curb Chain and Gourmette Chain

About Jewelry Chain- Figaro Chain

About Jewelry Chain- Figaro Chain

About Jewelry Chain- Infinity Chain and Anchor Chain

About Jewelry Chain- Infinity Chain and Anchor Chain

About Jewelry Chain- Chain Reference Sheet

About Jewelry Chain- Chain Reference Sheet

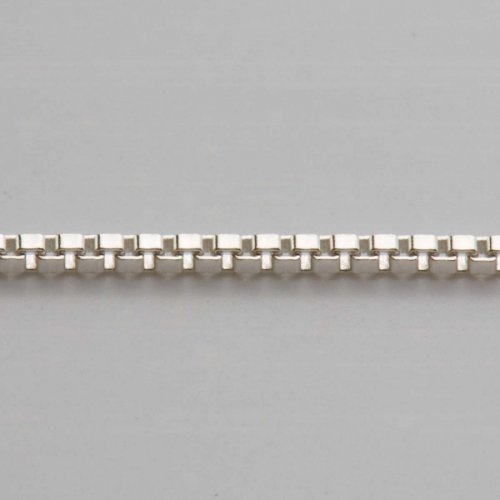

About Jewelry Chain- Venetian Chain and Box Chain

About Jewelry Chain- Venetian Chain and Box Chain

About Jewelry Chain- Wheat Chain and Rope Chain

About Jewelry Chain- Wheat Chain and Rope Chain

Introduction to Chain

Introduction to Chain

Access More Money by Making Jewelry When Your Prices Are Right

Access More Money by Making Jewelry When Your Prices Are Right

An Introduction to Beads and Beading

An Introduction to Beads and Beading

Common Gemstone Misconceptions

Common Gemstone Misconceptions

Wire Wrapped Christmas Tree

Wire Wrapped Christmas Tree

How To Polish Metal Jewelry using a Rotary Tumbler

How To Polish Metal Jewelry using a Rotary Tumbler

How To Polish Your Own Rocks using a Rotary Rock Tumbler

How To Polish Your Own Rocks using a Rotary Rock Tumbler

How to Merchandise Your Jewelry on the Internet

How to Merchandise Your Jewelry on the Internet

How to Use Twitter as a Wire Jewelry Artist

How to Use Twitter as a Wire Jewelry Artist

20 Ideas to get your Jewelry Biz Busy

20 Ideas to get your Jewelry Biz Busy

Watching the Precious Metals Market

Watching the Precious Metals Market

Jewelry Design Ideas - Get Inspired

Jewelry Design Ideas - Get Inspired

Measuring Tools

Measuring Tools

July Birthstone - The Ruby

July Birthstone - The Ruby

February Birthstone- Amethyst

February Birthstone- Amethyst

March Birthstone - Aquamarine and Bloodstone

March Birthstone - Aquamarine and Bloodstone

September Birthstone - Sapphire

September Birthstone - Sapphire

November Birthstones - Topaz and Citrine

November Birthstones - Topaz and Citrine

October Birthstones - Rose Zircon, Pink Tourmaline and Opal

October Birthstones - Rose Zircon, Pink Tourmaline and Opal

April Birthstone - The Diamond

April Birthstone - The Diamond

August Birthstone - Peridot and Sardonyx

August Birthstone - Peridot and Sardonyx

June Birthstones - Alexandrite, Pearl and Moonstone

June Birthstones - Alexandrite, Pearl and Moonstone

Metalsmithing

Metalsmithing

Featured Tool - Mini TruStrike Hammers

Featured Tool - Mini TruStrike Hammers

Natural Jasper Stones - Cabochon Gemstones

Natural Jasper Stones - Cabochon Gemstones

Organize Your Jewelry Box

Organize Your Jewelry Box

Pearls- It's a Cultural Thing

Pearls- It's a Cultural Thing

Starting Your Own Home Jewelry Business

Starting Your Own Home Jewelry Business

The Art of Creating Chainmail

The Art of Creating Chainmail

Why Should I Be Using Facebook

Why Should I Be Using Facebook

Make Handmade Neck Cords on a Dime

Make Handmade Neck Cords on a Dime

Tagging Handmade Jewelry Gifts

Tagging Handmade Jewelry Gifts

Share Your Expertise with Your Community

Share Your Expertise with Your Community

Creating Color Schemes for Jewelry Making

Creating Color Schemes for Jewelry Making

Bronze, Brass, Nickel Silver and Copper Base Metals

Bronze, Brass, Nickel Silver and Copper Base Metals

Gemstone Treatments

Gemstone Treatments

How Wire is Made

How Wire is Made

Beading A-B-C's

Beading A-B-C's

How to Set Up Your Workspace

How to Set Up Your Workspace

Gem Profile- Diamond

Gem Profile- Diamond

Gem Profile- Peridot

Gem Profile- Peridot

Gem Profile- Goldstone

Gem Profile- Goldstone

Gem Profile- Cryptocrystalline Quartz Introduction

Gem Profile- Cryptocrystalline Quartz Introduction

Gem Profile- Banded Agate and Brecciated Agate

Gem Profile- Banded Agate and Brecciated Agate

Gem Profile- Emerald

Gem Profile- Emerald

Gem Profile- Titanite or Sphene

Gem Profile- Titanite or Sphene

Gem Profile- Morganite

Gem Profile- Morganite

Gem Profile- Desert Rose

Gem Profile- Desert Rose

Gem Profile- Iolite

Gem Profile- Iolite

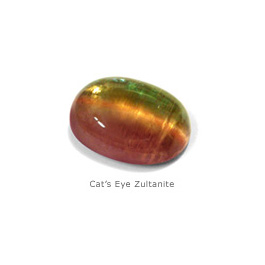

Gem Profile- Zultanite

Gem Profile- Zultanite

Gem Profile- Maw Sit Sit

Gem Profile- Maw Sit Sit

Gem Profile- Tanzanite

Gem Profile- Tanzanite

Gem Profile- Aquamarine

Gem Profile- Aquamarine

Gem Profile- Turquoise

Gem Profile- Turquoise

Gem Profile- Turquoise Types

Gem Profile- Turquoise Types

Gem Profile- What's Druze

Gem Profile- What's Druze

Gem Profile- Basalt

Gem Profile- Basalt

Gem Profile- Fordite

Gem Profile- Fordite

Gem Profile- Variscite

Gem Profile- Variscite

Gem Profile- Pearls

Gem Profile- Pearls

Gem Profile- Onyx

Gem Profile- Onyx

Gem Profile- Sunstone

Gem Profile- Sunstone

Gem Profile- Sonora Sunrise

Gem Profile- Sonora Sunrise

Gem Profile- Rhodonite

Gem Profile- Rhodonite

Gem Profile- Glass, Crystal and Quartz

Gem Profile- Glass, Crystal and Quartz

Gem Profile- Psilomelane

Gem Profile- Psilomelane

Gem Profile- Fulgurite

Gem Profile- Fulgurite

Gem Profile- Cat's Eye

Gem Profile- Cat's Eye

Gem Profile- Carnelian

Gem Profile- Carnelian

Gem Profile- Petoskey Stones and Indonesian Fossil Coral

Gem Profile- Petoskey Stones and Indonesian Fossil Coral

Gem Profile- Rutilated Quartz

Gem Profile- Rutilated Quartz

Gem Profile- Chrysocolla

Gem Profile- Chrysocolla

Gem Profile- Jet

Gem Profile- Jet

Gem Profile- Chrysoprase

Gem Profile- Chrysoprase

Gem Profile- Rhyolite

Gem Profile- Rhyolite

Gem Profile- Chalcedony

Gem Profile- Chalcedony

Gem Profile- Lepidolite and Sugilite

Gem Profile- Lepidolite and Sugilite

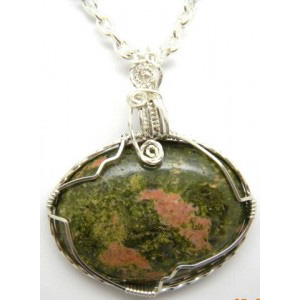

Gem Profile- Unakite

Gem Profile- Unakite

Gem Profile- Cowrie Shells, Conch Shells, and Drilling Shells

Gem Profile- Cowrie Shells, Conch Shells, and Drilling Shells

Gem Profile- Mother of Pearl

Gem Profile- Mother of Pearl

Gem Profile- Moss Agate and Plume Agate

Gem Profile- Moss Agate and Plume Agate

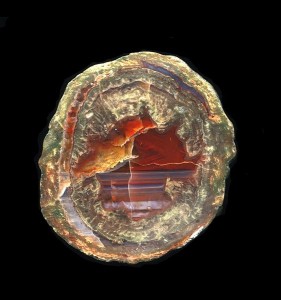

Gem Profile- Thundereggs and Mexican Lace Agate

Gem Profile- Thundereggs and Mexican Lace Agate

Gem Profile- Dumortierite

Gem Profile- Dumortierite

Gem Profile- Apatite

Gem Profile- Apatite

Gem Profile- Blue Topaz

Gem Profile- Blue Topaz

Gem Profile- Aragonite

Gem Profile- Aragonite

Gem Profile- Zircon and Cubic Zirconia

Gem Profile- Zircon and Cubic Zirconia

Gem Profile- Topaz

Gem Profile- Topaz

Gem Profile- Howlite

Gem Profile- Howlite

Gem Profile- Sodalite

Gem Profile- Sodalite

Gem Profile- Magnesite

Gem Profile- Magnesite

Gem Profile- Cuprite

Gem Profile- Cuprite

Gem Profile- Nuummite

Gem Profile- Nuummite

Gem Profile- Bronzite

Gem Profile- Bronzite

Gem Profile- Kyanite

Gem Profile- Kyanite

Gem Profile- Hematite

Gem Profile- Hematite

Gem Profile- Derbyshire Blue John

Gem Profile- Derbyshire Blue John

Gem Profile- Eilat Stone

Gem Profile- Eilat Stone

Gem Profile- Vesuvianite

Gem Profile- Vesuvianite

Gem Profile- Strontium Titanate -Fabulite

Gem Profile- Strontium Titanate -Fabulite

Gem Profile- Tourmaline

Gem Profile- Tourmaline

Gem Profile- Larimar

Gem Profile- Larimar

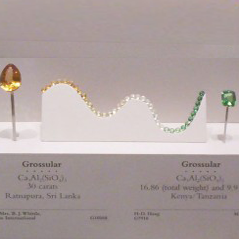

Gem Profile- Garnet

Gem Profile- Garnet

Gem Profile- Tsavorite and Green Garnets

Gem Profile- Tsavorite and Green Garnets

Gem Profile- Seraphinite

Gem Profile- Seraphinite

Gem Profile- Serpentine

Gem Profile- Serpentine

American Wire Gauge

American Wire Gauge

Viking Knit and Spool Knit Chain

Viking Knit and Spool Knit Chain

Copper Roses

Copper Roses

How to Make Medical ID Bracelets Special

How to Make Medical ID Bracelets Special

Remembering the Fallen

Remembering the Fallen

6 Ways to Find Your Uniqueness in Jewelry

6 Ways to Find Your Uniqueness in Jewelry

Gem Profile- Moissanite

Gem Profile- Moissanite

Birthstone Swarovski Colors

Birthstone Swarovski Colors

Gem profile- Paua and Abalone

Gem profile- Paua and Abalone

Tips for Tucson Shopping- Gem Show Secrets

Tips for Tucson Shopping- Gem Show Secrets

Durston Olivia Rolling Mills

Durston Olivia Rolling Mills

How to Use a Jewelry Bench Polisher Effectively

How to Use a Jewelry Bench Polisher Effectively

5 Jewelry Patterns to Keep Summer Going

5 Jewelry Patterns to Keep Summer Going

Why Jewelry Makers Love Boho And Free-Form Designs

Why Jewelry Makers Love Boho And Free-Form Designs

5 Fall Leaf Jewelry Patterns to Capture the Colors of Autumn

5 Fall Leaf Jewelry Patterns to Capture the Colors of Autumn

Bold Gemstone Wire Jewelry Tutorials for Beginners

Bold Gemstone Wire Jewelry Tutorials for Beginners

Why Remodeling Old Designs Saves You Money and Sparks Creativity

Why Remodeling Old Designs Saves You Money and Sparks Creativity

Make Something Magical This Halloween Season

Make Something Magical This Halloween Season

5 Must-Make Holiday Jewelry Projects That Bring the Festive Fun

5 Must-Make Holiday Jewelry Projects That Bring the Festive Fun

Our Most-Loved Jewelry-Making Patterns of 2025

Our Most-Loved Jewelry-Making Patterns of 2025

Our Most-Loved Jewelry-Making Tips And Techniques of 2025

Our Most-Loved Jewelry-Making Tips And Techniques of 2025