How Wire is Made

The term "wire wrapping" is a bit like "suntan."

When you get a suntan (soon, people!), you show off your bronzed skin - it's all about the tan. As for the sun's role? Well, it's there somewhere.

So it is with wire wrapping. Who, really, thinks about the wire? (OK, except for you home metallurgists getting ready to email me.) When someone admires your beautifully wrapped pendent, they're not thinking: "Where did that wire come from?"

When you get a suntan (soon, people!), you show off your bronzed skin - it's all about the tan. As for the sun's role? Well, it's there somewhere.

So it is with wire wrapping. Who, really, thinks about the wire? (OK, except for you home metallurgists getting ready to email me.) When someone admires your beautifully wrapped pendent, they're not thinking: "Where did that wire come from?"

It seems that wire, like the sun, is taken for granted. So, we wanted to correct that oversight, give appreciation where it's due.

After a bit of research, I've gained more respect for the lowly paper clip, and particularly for the fine wire we carry here at Wire-Sculpture.

I've also learned that I can make (someday!) my own wire - yep, I didn't know that was even possible.

After a bit of research, I've gained more respect for the lowly paper clip, and particularly for the fine wire we carry here at Wire-Sculpture.

I've also learned that I can make (someday!) my own wire - yep, I didn't know that was even possible.

How Wire was Made - In the Beginning

Wire dates back to Egypt's 2nd Dynasty, around 2600 BC.

Its purpose was jewelry and chains.

Ancient Egyptians pounded metal into sheets, then sliced them into strips.

They twisted or rolled the strips to create seamed wire.

The Etruscans, absorbed by ancient Romans, made short wire lengths using anvil, fire, and hammer.

Wire dates back to Egypt's 2nd Dynasty, around 2600 BC.

Its purpose was jewelry and chains.

Ancient Egyptians pounded metal into sheets, then sliced them into strips.

They twisted or rolled the strips to create seamed wire.

The Etruscans, absorbed by ancient Romans, made short wire lengths using anvil, fire, and hammer.

Draw Plates Changed the Game

Early wire-making methods stayed advanced until medieval times.

An English craftsman invented pulling metal through a small hole in a drawplate.

This wire drawing process is still used today.

Medieval people used wire for practical items, like wool-carding brushes.

Wire returned to decorative uses, such as brooches and necklaces, in the Victorian era.

Early wire-making methods stayed advanced until medieval times.

An English craftsman invented pulling metal through a small hole in a drawplate.

This wire drawing process is still used today.

Medieval people used wire for practical items, like wool-carding brushes.

Wire returned to decorative uses, such as brooches and necklaces, in the Victorian era.

Now Wire Mills are Highly Mechanized

Wire-making has evolved into a highly mechanized industry.

The process still follows basic steps from centuries ago, with electricity replacing brute strength.

Strips of metal are pounded or rolled into shape.

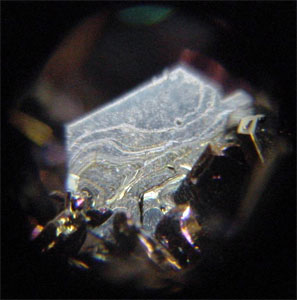

They are pulled through a funnel-like hole in a cast-iron or diamond drawplate.

As wire is drawn through, its diameter reduces and length increases.

Progressive smaller openings make it thinner.

Round wire is most common.

Special drawplates create half-round and square shapes.

Wire reduces in increments of about one-tenth millimeter.

Final hole size sets the gauge.

To start, file or pound the wire end to a point.

Attach pincers and pull through using a winch or tension pulley.

Before electricity, laborers grunted and sweated, cranking by hand.

This technique persists in home metal shops today.

Yes, the grunting and sweating still happen!

Wire-making has evolved into a highly mechanized industry.

The process still follows basic steps from centuries ago, with electricity replacing brute strength.

Strips of metal are pounded or rolled into shape.

They are pulled through a funnel-like hole in a cast-iron or diamond drawplate.

As wire is drawn through, its diameter reduces and length increases.

Progressive smaller openings make it thinner.

Round wire is most common.

Special drawplates create half-round and square shapes.

Wire reduces in increments of about one-tenth millimeter.

Final hole size sets the gauge.

To start, file or pound the wire end to a point.

Attach pincers and pull through using a winch or tension pulley.

Before electricity, laborers grunted and sweated, cranking by hand.

This technique persists in home metal shops today.

Yes, the grunting and sweating still happen!

Wire Hardness

Working with metal hardens it.

You've likely hammered jewelry to prevent bending.

Wire temper relates directly to the drawing process.

Wire hardness was once measured from 0 to 4.

Softest wire (0) passed through the die once.

Hardness 2 meant twice, and 4 meant five or more times.

Each pass stiffened and strengthened it.

Today, wire is sold as dead soft, half-hard, or full hard.

Dead soft equals hardness 0.

Half-hard equals 2.

Full hard equals 4.

Copper jewelry wire passes through 10 or more drawplates.

It anneals every few stages to soften.

Telephone wire draws up to 20 times while hot.

Modern artisans use these steps with silver and gold.

Check this link for a craftsman's step-by-step process.

Now I appreciate wire more.

Time to step outside for a suntan!

Working with metal hardens it.

You've likely hammered jewelry to prevent bending.

Wire temper relates directly to the drawing process.

Wire hardness was once measured from 0 to 4.

Softest wire (0) passed through the die once.

Hardness 2 meant twice, and 4 meant five or more times.

Each pass stiffened and strengthened it.

Today, wire is sold as dead soft, half-hard, or full hard.

Dead soft equals hardness 0.

Half-hard equals 2.

Full hard equals 4.

Copper jewelry wire passes through 10 or more drawplates.

It anneals every few stages to soften.

Telephone wire draws up to 20 times while hot.

Modern artisans use these steps with silver and gold.

Check this link for a craftsman's step-by-step process.

Now I appreciate wire more.

Time to step outside for a suntan!

Resource: Wikipedia

Materials

Wire

Tools

Rosewood Draw Plate for Vise

G28-7

- G28-7

- Lesson Quantity: 1.00 pieces

- Purchase Quantity: 1.00 each

- Price: $17.97

- Gold Club Price: $13.48

Rosewood Handheld Draw Plate

G28-8

- G28-8

- Lesson Quantity: 1.00 pieces

- Purchase Quantity: 1.00 each

- Price: $17.97

- Gold Club Price: $13.48

Draw Plate

DRA-410.00

- DRA-410.00

- Lesson Quantity: 1.00 pieces

- Purchase Quantity: 1.00 each

- Category: General Education

- Technique(s): Tools, General Education

About Jewelry Chain- About Ball Chain

About Jewelry Chain- About Ball Chain

About Jewelry Chain- Snake Chain and Omega Chain

About Jewelry Chain- Snake Chain and Omega Chain

About Jewelry Chain- Bar Chain and Peanut Chain

About Jewelry Chain- Bar Chain and Peanut Chain

About Jewelry Chain - Cable Chain and Rolo Chain

About Jewelry Chain - Cable Chain and Rolo Chain

About Jewelry Chain- Curb Chain and Gourmette Chain

About Jewelry Chain- Curb Chain and Gourmette Chain

About Jewelry Chain- Figaro Chain

About Jewelry Chain- Figaro Chain

About Jewelry Chain- Infinity Chain and Anchor Chain

About Jewelry Chain- Infinity Chain and Anchor Chain

About Jewelry Chain- Chain Reference Sheet

About Jewelry Chain- Chain Reference Sheet

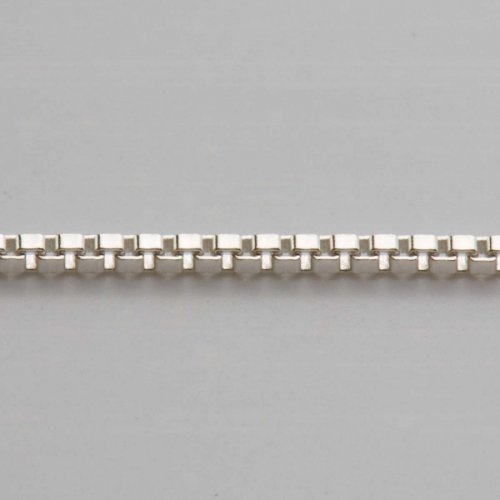

About Jewelry Chain- Venetian Chain and Box Chain

About Jewelry Chain- Venetian Chain and Box Chain

About Jewelry Chain- Wheat Chain and Rope Chain

About Jewelry Chain- Wheat Chain and Rope Chain

Introduction to Chain

Introduction to Chain

Access More Money by Making Jewelry When Your Prices Are Right

Access More Money by Making Jewelry When Your Prices Are Right

An Introduction to Beads and Beading

An Introduction to Beads and Beading

Common Gemstone Misconceptions

Common Gemstone Misconceptions

Wire Wrapped Christmas Tree

Wire Wrapped Christmas Tree

How To Polish Metal Jewelry using a Rotary Tumbler

How To Polish Metal Jewelry using a Rotary Tumbler

How To Polish Your Own Rocks using a Rotary Rock Tumbler

How To Polish Your Own Rocks using a Rotary Rock Tumbler

How to Merchandise Your Jewelry on the Internet

How to Merchandise Your Jewelry on the Internet

How to Use Twitter as a Wire Jewelry Artist

How to Use Twitter as a Wire Jewelry Artist

20 Ideas to get your Jewelry Biz Busy

20 Ideas to get your Jewelry Biz Busy

Watching the Precious Metals Market

Watching the Precious Metals Market

Jewelry Design Ideas - Get Inspired

Jewelry Design Ideas - Get Inspired

Measuring Tools

Measuring Tools

July Birthstone - The Ruby

July Birthstone - The Ruby

February Birthstone- Amethyst

February Birthstone- Amethyst

March Birthstone - Aquamarine and Bloodstone

March Birthstone - Aquamarine and Bloodstone

September Birthstone - Sapphire

September Birthstone - Sapphire

November Birthstones - Topaz and Citrine

November Birthstones - Topaz and Citrine

October Birthstones - Rose Zircon, Pink Tourmaline and Opal

October Birthstones - Rose Zircon, Pink Tourmaline and Opal

April Birthstone - The Diamond

April Birthstone - The Diamond

August Birthstone - Peridot and Sardonyx

August Birthstone - Peridot and Sardonyx

June Birthstones - Alexandrite, Pearl and Moonstone

June Birthstones - Alexandrite, Pearl and Moonstone

Metalsmithing

Metalsmithing

Featured Tool - Mini TruStrike Hammers

Featured Tool - Mini TruStrike Hammers

Natural Jasper Stones - Cabochon Gemstones

Natural Jasper Stones - Cabochon Gemstones

Organize Your Jewelry Box

Organize Your Jewelry Box

Pearls- It's a Cultural Thing

Pearls- It's a Cultural Thing

Soldering 101

Soldering 101

Starting Your Own Home Jewelry Business

Starting Your Own Home Jewelry Business

The Art of Creating Chainmail

The Art of Creating Chainmail

Why Should I Be Using Facebook

Why Should I Be Using Facebook

Make Handmade Neck Cords on a Dime

Make Handmade Neck Cords on a Dime

Tagging Handmade Jewelry Gifts

Tagging Handmade Jewelry Gifts

Share Your Expertise with Your Community

Share Your Expertise with Your Community

Creating Color Schemes for Jewelry Making

Creating Color Schemes for Jewelry Making

Bronze, Brass, Nickel Silver and Copper Base Metals

Bronze, Brass, Nickel Silver and Copper Base Metals

Gemstone Treatments

Gemstone Treatments

Beading A-B-C's

Beading A-B-C's

How to Set Up Your Workspace

How to Set Up Your Workspace

Gem Profile- Diamond

Gem Profile- Diamond

Gem Profile- Peridot

Gem Profile- Peridot

Gem Profile- Goldstone

Gem Profile- Goldstone

Gem Profile- Cryptocrystalline Quartz Introduction

Gem Profile- Cryptocrystalline Quartz Introduction

Gem Profile- Banded Agate and Brecciated Agate

Gem Profile- Banded Agate and Brecciated Agate

Gem Profile- Emerald

Gem Profile- Emerald

Gem Profile- Titanite or Sphene

Gem Profile- Titanite or Sphene

Gem Profile- Morganite

Gem Profile- Morganite

Gem Profile- Desert Rose

Gem Profile- Desert Rose

Gem Profile- Iolite

Gem Profile- Iolite

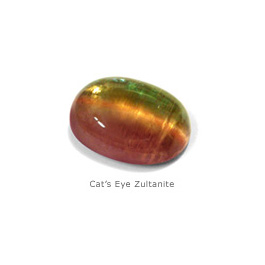

Gem Profile- Zultanite

Gem Profile- Zultanite

Gem Profile- Maw Sit Sit

Gem Profile- Maw Sit Sit

Gem Profile- Tanzanite

Gem Profile- Tanzanite

Gem Profile- Aquamarine

Gem Profile- Aquamarine

Gem Profile- Turquoise

Gem Profile- Turquoise

Gem Profile- Turquoise Types

Gem Profile- Turquoise Types

Gem Profile- What's Druze

Gem Profile- What's Druze

Gem Profile- Basalt

Gem Profile- Basalt

Gem Profile- Fordite

Gem Profile- Fordite

Gem Profile- Variscite

Gem Profile- Variscite

Gem Profile- Pearls

Gem Profile- Pearls

Gem Profile- Onyx

Gem Profile- Onyx

Gem Profile- Sunstone

Gem Profile- Sunstone

Gem Profile- Sonora Sunrise

Gem Profile- Sonora Sunrise

Gem Profile- Rhodonite

Gem Profile- Rhodonite

Gem Profile- Glass, Crystal and Quartz

Gem Profile- Glass, Crystal and Quartz

Gem Profile- Psilomelane

Gem Profile- Psilomelane

Gem Profile- Fulgurite

Gem Profile- Fulgurite

Gem Profile- Cat's Eye

Gem Profile- Cat's Eye

Gem Profile- Carnelian

Gem Profile- Carnelian

Gem Profile- Petoskey Stones and Indonesian Fossil Coral

Gem Profile- Petoskey Stones and Indonesian Fossil Coral

Gem Profile- Rutilated Quartz

Gem Profile- Rutilated Quartz

Gem Profile- Chrysocolla

Gem Profile- Chrysocolla

Gem Profile- Jet

Gem Profile- Jet

Gem Profile- Chrysoprase

Gem Profile- Chrysoprase

Gem Profile- Rhyolite

Gem Profile- Rhyolite

Gem Profile- Chalcedony

Gem Profile- Chalcedony

Gem Profile- Lepidolite and Sugilite

Gem Profile- Lepidolite and Sugilite

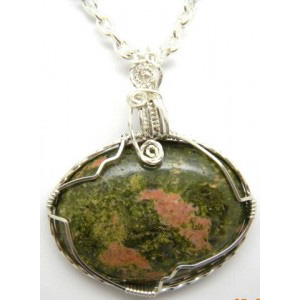

Gem Profile- Unakite

Gem Profile- Unakite

Gem Profile- Cowrie Shells, Conch Shells, and Drilling Shells

Gem Profile- Cowrie Shells, Conch Shells, and Drilling Shells

Gem Profile- Mother of Pearl

Gem Profile- Mother of Pearl

Gem Profile- Moss Agate and Plume Agate

Gem Profile- Moss Agate and Plume Agate

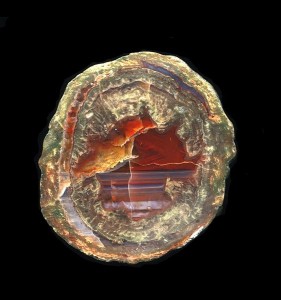

Gem Profile- Thundereggs and Mexican Lace Agate

Gem Profile- Thundereggs and Mexican Lace Agate

Gem Profile- Dumortierite

Gem Profile- Dumortierite

Gem Profile- Apatite

Gem Profile- Apatite

Gem Profile- Blue Topaz

Gem Profile- Blue Topaz

Gem Profile- Aragonite

Gem Profile- Aragonite

Gem Profile- Zircon and Cubic Zirconia

Gem Profile- Zircon and Cubic Zirconia

Gem Profile- Topaz

Gem Profile- Topaz

Gem Profile- Howlite

Gem Profile- Howlite

Gem Profile- Sodalite

Gem Profile- Sodalite

Gem Profile- Magnesite

Gem Profile- Magnesite

Gem Profile- Cuprite

Gem Profile- Cuprite

Gem Profile- Nuummite

Gem Profile- Nuummite

Gem Profile- Bronzite

Gem Profile- Bronzite

Gem Profile- Kyanite

Gem Profile- Kyanite

Gem Profile- Hematite

Gem Profile- Hematite

Gem Profile- Derbyshire Blue John

Gem Profile- Derbyshire Blue John

Gem Profile- Eilat Stone

Gem Profile- Eilat Stone

Gem Profile- Vesuvianite

Gem Profile- Vesuvianite

Gem Profile- Strontium Titanate -Fabulite

Gem Profile- Strontium Titanate -Fabulite

Gem Profile- Tourmaline

Gem Profile- Tourmaline

Gem Profile- Larimar

Gem Profile- Larimar

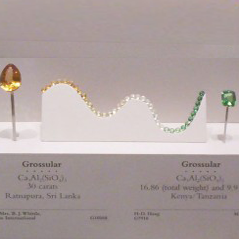

Gem Profile- Garnet

Gem Profile- Garnet

Gem Profile- Tsavorite and Green Garnets

Gem Profile- Tsavorite and Green Garnets

Gem Profile- Seraphinite

Gem Profile- Seraphinite

Gem Profile- Serpentine

Gem Profile- Serpentine

American Wire Gauge

American Wire Gauge

Viking Knit and Spool Knit Chain

Viking Knit and Spool Knit Chain

Copper Roses

Copper Roses

How to Make Medical ID Bracelets Special

How to Make Medical ID Bracelets Special

Remembering the Fallen

Remembering the Fallen

6 Ways to Find Your Uniqueness in Jewelry

6 Ways to Find Your Uniqueness in Jewelry

Gem Profile- Moissanite

Gem Profile- Moissanite

Birthstone Swarovski Colors

Birthstone Swarovski Colors

Gem profile- Paua and Abalone

Gem profile- Paua and Abalone

Tips for Tucson Shopping- Gem Show Secrets

Tips for Tucson Shopping- Gem Show Secrets

Durston Olivia Rolling Mills

Durston Olivia Rolling Mills

How to Use a Jewelry Bench Polisher Effectively

How to Use a Jewelry Bench Polisher Effectively

5 Jewelry Patterns to Keep Summer Going

5 Jewelry Patterns to Keep Summer Going

Why Jewelry Makers Love Boho And Free-Form Designs

Why Jewelry Makers Love Boho And Free-Form Designs

5 Fall Leaf Jewelry Patterns to Capture the Colors of Autumn

5 Fall Leaf Jewelry Patterns to Capture the Colors of Autumn

Bold Gemstone Wire Jewelry Tutorials for Beginners

Bold Gemstone Wire Jewelry Tutorials for Beginners

Why Remodeling Old Designs Saves You Money and Sparks Creativity

Why Remodeling Old Designs Saves You Money and Sparks Creativity

Make Something Magical This Halloween Season

Make Something Magical This Halloween Season

5 Must-Make Holiday Jewelry Projects That Bring the Festive Fun

5 Must-Make Holiday Jewelry Projects That Bring the Festive Fun

Our Most-Loved Jewelry-Making Patterns of 2025

Our Most-Loved Jewelry-Making Patterns of 2025

Our Most-Loved Jewelry-Making Tips And Techniques of 2025

Our Most-Loved Jewelry-Making Tips And Techniques of 2025