An Adventure in Water Casting

I felt like Alice in Wonderland as I started the journey into water casting. I've barely scratched the surface but I have had so much fun learning and creating with this wonderful technique.

The basics: dripping molten silver into water produces fun shapes, often little cups.

The results vary widely, including balls, cornflakes, cups, and some unusual forms.

One goal of this experiment was to discover what conditions create the most consistent, reliable, and attractive cup shapes.

The results vary widely, including balls, cornflakes, cups, and some unusual forms.

One goal of this experiment was to discover what conditions create the most consistent, reliable, and attractive cup shapes.

I got my materials ready.

I wanted to see how different gauges of wire affected the size and shape of cups.

I started with 12 gauge, 14 gauge and 16 gauge silver

I wanted to see how different gauges of wire affected the size and shape of cups.

I started with 12 gauge, 14 gauge and 16 gauge silver

Then decided to add 16 gauge brass, 16 gauge bronze and 16 gauge copper to the pile to see what happens.

The two torches I used are a Smith Acetylene/Air torch and a Euro tool Torch Head with a butane canister.

A small creme brulee-type torch will not work well for this project.

A small creme brulee-type torch will not work well for this project.

I chilled the water until it was ice cold, with no ice chunks visible, and used a large glass vase filled with more than 6 inches of cold water to drop the silver into.

The vase was placed on a metal stool at a comfortable height, near my bench for safety.

I had a fire extinguisher nearby, my hair tied back, safety glasses on, and wore a mask.

Windows were open for cross ventilation. I don't expect any problems, but I want to be prepared because what could go wrong with fire, molten silver, and ice water?

The vase was placed on a metal stool at a comfortable height, near my bench for safety.

I had a fire extinguisher nearby, my hair tied back, safety glasses on, and wore a mask.

Windows were open for cross ventilation. I don't expect any problems, but I want to be prepared because what could go wrong with fire, molten silver, and ice water?

My plan was simple, test each metal with both torches and see the results.

I start off with the acetylene torch and lit it up. I use a pair of long nose pliers to handle the metal.

These are not metalsmithing pliers but ones I picked up at the hardware store.

With 12 gauge silver in hand, I started melting silver.

I kept the end of the wire at least 6" from the top of the water, aimed the torch up, heating from the bottom.

I start off with the acetylene torch and lit it up. I use a pair of long nose pliers to handle the metal.

These are not metalsmithing pliers but ones I picked up at the hardware store.

With 12 gauge silver in hand, I started melting silver.

I kept the end of the wire at least 6" from the top of the water, aimed the torch up, heating from the bottom.

Below are the results:

1. 12 Gauge Sterling Silver Wire

a. Acetylene Torch

1. 12 Gauge Sterling Silver Wire

a. Acetylene Torch

b. Butane Torch

2. 14 Gauge Sterling Silver Wire

2. 14 Gauge Sterling Silver Wire

a. Acetylene Torch

b. Butane Torch

3. 16 Gauge Sterling Silver Wire

a. Acetylene Torch

b. Butane Torch

a. Acetylene Torch

b. Butane Torch

4. 16 Gauge Bronze Wire

a. Acetylene Torch

a. Acetylene Torch

5. 16 Gauge Brass Wire

a. Acetylene Torch

a. Acetylene Torch

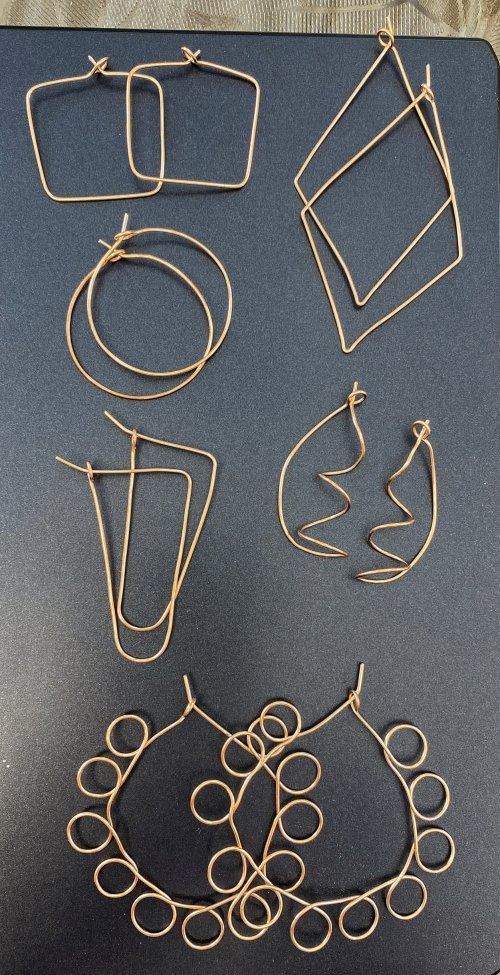

6. 16 Gauge Copper Wire

a. Acetylene Torch

a. Acetylene Torch

The last photo, Photo 18, is all of the metals with their respective cups

Acetylene cups are on the top row and the butane cups are on the bottom row.

Acetylene cups are on the top row and the butane cups are on the bottom row.

My conclusions: The hotter the torch, the better and more consistent the water-cast cups.

Thicker gauge wire produces more rounded, well-shaped cups, while 16-gauge wire made cups with pointy bottoms.

The butane torch took longer to melt the wire, especially thicker wire, resulting in less uniform cups.

With 16-gauge wire and the butane torch, I also got cornflakes and odd shapes.

When the water warms, cups develop pointy bottoms too.

Other metals like brass, bronze, and copper did NOT form cups they mostly became balls or misshapen blobs.

I plan to experiment more with these metals, perhaps by melting the metal closer to the water or using deeper water.

The cups made from water casting have many uses. What will you make?

Thicker gauge wire produces more rounded, well-shaped cups, while 16-gauge wire made cups with pointy bottoms.

The butane torch took longer to melt the wire, especially thicker wire, resulting in less uniform cups.

With 16-gauge wire and the butane torch, I also got cornflakes and odd shapes.

When the water warms, cups develop pointy bottoms too.

Other metals like brass, bronze, and copper did NOT form cups they mostly became balls or misshapen blobs.

I plan to experiment more with these metals, perhaps by melting the metal closer to the water or using deeper water.

The cups made from water casting have many uses. What will you make?

Materials

14 Gauge Round Half Hard .925 Sterling Silver Wire

H8-14H

- Lesson Quantity: 1.00 pieces

- Purchase Quantity: 1.00 1FT

- Price: $60.97

- Gold Club Price: $45.73

12 Gauge Round Dead Soft .925 Sterling Silver Wire

H8-12D

- Lesson Quantity: 1.00 pieces

- Purchase Quantity: 1.00 1FT

- Price: $97.26

- Gold Club Price: $72.94

16 Gauge Round Half Hard .925 Sterling Silver Wire

H8-16H

- Lesson Quantity: 1.00 pieces

- Purchase Quantity: 1.00 1FT

- Price: $39.19

- Gold Club Price: $29.40

16 Gauge Round Dead Soft Red Brass Wire

H3-16D

- Lesson Quantity: 1.00 pieces

- Purchase Quantity: 1.00 1FT

- Price: $1.71

- Gold Club Price: $1.28

16 Gauge Round Dead Soft Yellow Brass Wire

H1-16D

- Lesson Quantity: 1.00 pieces

- Purchase Quantity: 1.00 1FT

- Price: $1.21

- Gold Club Price: $0.91

16 Gauge Round Dead Soft Copper Wire

H11-16D

- Lesson Quantity: 1.00 pieces

- Purchase Quantity: 1.00 1FT

- Price: $1.13

- Gold Club Price: $0.84

Tools

Basic Soldering Kit

G15-4

- G15-4

- Lesson Quantity: 1.00 pieces

- Purchase Quantity: 1.00 each

- Price: $58.95

- Gold Club Price: $44.21

6.5 Inch Long Flat Nose Pliers - Pack of 1

G2-74

- G2-74

- Lesson Quantity: 1.00 pieces

- Purchase Quantity: 1.00 each

- Price: $9.87

- Gold Club Price: $7.40

Complete Small Torch Kit with Regulators

G32-1

- G32-1

- Lesson Quantity: 1.00 pieces

- Purchase Quantity: 1.00 each

- Price: $349.97

- Gold Club Price: $262.48

Just Face It - Discover Casting with Pewter Taught By: Kim St. Jean

TS_2019_02_08_STJEAN

- TS_2019_02_08_STJEAN

- Lesson Quantity: 1.00 pieces

- Purchase Quantity: 1.00 each

- Price: $89.00

- Gold Club Price: $66.75

12x12 Inch Rubber Mat

MAT-500.00

- MAT-500.00

- Lesson Quantity: 1.00 pieces

- Purchase Quantity: 1.00 each

- Price: $24.95

- Gold Club Price: $18.71

- Category: General Education

- Technique(s): Butane Torch Techniques

The Final Steps for Finishing Ear Wires

The Final Steps for Finishing Ear Wires

Sealing and Protecting Your Work

Sealing and Protecting Your Work

A Journey in Creating Hoop Earrings

A Journey in Creating Hoop Earrings

Not Just a Concept

Not Just a Concept