All About Rolling Mills

I am what you would consider a weekend jewelry maker. There are some tools I will invest more money in because I use them quite often and want them to last. A case in point would be pliers. I own quite a few Lindstrom RX Ergonomic pliers and love them. They are much easier than other pliers on my arthritic hands. I do, however, use my craft store pliers for many things. I always advise beginners to purchase a moderately priced set because they don't know if they will continue making jewelry. After a while, if they want to upgrade tools, I suggest the best tools they can afford because they do make a difference.

One of the most important questions to ask when buying new tools or equipment is how much you will use them.

If the answer is "a lot," buy the best you can afford.

Two years ago, I bought a rolling mill. It was a "want" for years, not a need.

I chose a mid-range quality mill because I'm 70 and wouldn't use it as many years as if I were younger.

My only must-have was covered crank gears for safety, especially with small grandchildren around.

Since my jewelry room doubles as a laundry with humidity the enemy of mill rollers I couldn't store it away safely.

I also didn't plan to make wire, so I skipped the extra rollers that might have been useful if I were younger.

When ordering, I didn't think about what to place it on, so I had to build a cabinet.

You must attach the mill to something VERY STABLE that will NOT MOVE.

Note: If the cabinet stands alone without being attached to another cabinet, wall, or floor, it won't work properly.

If the answer is "a lot," buy the best you can afford.

Two years ago, I bought a rolling mill. It was a "want" for years, not a need.

I chose a mid-range quality mill because I'm 70 and wouldn't use it as many years as if I were younger.

My only must-have was covered crank gears for safety, especially with small grandchildren around.

Since my jewelry room doubles as a laundry with humidity the enemy of mill rollers I couldn't store it away safely.

I also didn't plan to make wire, so I skipped the extra rollers that might have been useful if I were younger.

When ordering, I didn't think about what to place it on, so I had to build a cabinet.

You must attach the mill to something VERY STABLE that will NOT MOVE.

Note: If the cabinet stands alone without being attached to another cabinet, wall, or floor, it won't work properly.

The problem with mid- and lower-priced rolling mills is that they have no gear markings for setting the rollers.

When a rolling mill arrives, it comes in pieces covered in grease to prevent rust.

Assembly isn't difficult, but some models come without instructions. YouTube is a great resource.

It took me a while to get the rollers, gears, and T-crank set so they evenly impressed texture on metal.

I also learned how far to turn the T-crank (more expensive mills have a wheel crank) to get impressions in various metal gauges.

Last summer, after the grandchildren visited, I tried to use the mill to texture a new design but couldn't turn the crank.

Everything looked fine, so I started taking it apart and realized the roller gears and crank had been tampered with.

It took time and a lot of copper to realign the rollers, gears, and T-crank properly.

That's when I decided I needed gear markings.

When a rolling mill arrives, it comes in pieces covered in grease to prevent rust.

Assembly isn't difficult, but some models come without instructions. YouTube is a great resource.

It took me a while to get the rollers, gears, and T-crank set so they evenly impressed texture on metal.

I also learned how far to turn the T-crank (more expensive mills have a wheel crank) to get impressions in various metal gauges.

Last summer, after the grandchildren visited, I tried to use the mill to texture a new design but couldn't turn the crank.

Everything looked fine, so I started taking it apart and realized the roller gears and crank had been tampered with.

It took time and a lot of copper to realign the rollers, gears, and T-crank properly.

That's when I decided I needed gear markings.

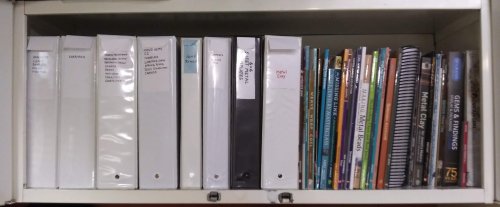

What a difference this has made for me! In a small spiral notebook I keep next to the mill, I make notes of everything I run through it and use those notes when I run something similar through.

No more practice test pieces for each project!

Make Notes:

In my notebook there are separate sections for each gauge and type of metal used.

That makes it easier to check for settings for the next project.

Note things such as the order of layering all the items used, was the metal annealed or not, what type folder was used, how good the impression was, impression distortion, etc..

No more practice test pieces for each project!

Make Notes:

In my notebook there are separate sections for each gauge and type of metal used.

That makes it easier to check for settings for the next project.

Note things such as the order of layering all the items used, was the metal annealed or not, what type folder was used, how good the impression was, impression distortion, etc..

Make Gear Calibration Markings

Step 1: Measure the diameter of the bolt and washer holding the gear in place.

Enlarge or reduce the photo to accommodate that size. I drew mine out but you may find something similar on the internet-Google Polar Grid Circle.

Since the gears turn in opposite directions, the numbers should go in opposite directions as well.

Enlarge or reduce the photo to accommodate that size. I drew mine out but you may find something similar on the internet-Google Polar Grid Circle.

Since the gears turn in opposite directions, the numbers should go in opposite directions as well.

Step 2 Print out the gear markings. Cover the top side with Contact paper or packing tape.

Step 3:Cut out the gear marking circles. Check the fit on the gears and adjust the hole or outer diameter as needed.

Step 4: Once sized to fit, run them through a permanent sticker maker. Alternatively, use wide double-stick tape (carpet tape works well) on the back.

Step 5: Clean the top of the gear with a paper towel and some alcohol to remove any oil or grease.

Step 6: Tighten the T-crank so the rollers press tightly together.

Hint: Make sure the metal feeds evenly through the mill without curving, which means one roller is pressing harder than the other.

Step 7: Decide where you want the zeros to be. I preferred them opposite each other with the T-crank horizontal to the zeros.

Look for a registration mark on the rolling mill box to help line up the zeros.

Before attaching the gear markings, turn the T-crank to ensure the numbers on the stickers turn in the correct direction mine ran backward the first time!

Step 8: You can use one or both gear marking circles. Having both makes recalibration easier if the mill is tampered with.

Step 3:Cut out the gear marking circles. Check the fit on the gears and adjust the hole or outer diameter as needed.

Step 4: Once sized to fit, run them through a permanent sticker maker. Alternatively, use wide double-stick tape (carpet tape works well) on the back.

Step 5: Clean the top of the gear with a paper towel and some alcohol to remove any oil or grease.

Step 6: Tighten the T-crank so the rollers press tightly together.

Hint: Make sure the metal feeds evenly through the mill without curving, which means one roller is pressing harder than the other.

Step 7: Decide where you want the zeros to be. I preferred them opposite each other with the T-crank horizontal to the zeros.

Look for a registration mark on the rolling mill box to help line up the zeros.

Before attaching the gear markings, turn the T-crank to ensure the numbers on the stickers turn in the correct direction mine ran backward the first time!

Step 8: You can use one or both gear marking circles. Having both makes recalibration easier if the mill is tampered with.

Deciding What Setting to Use

After setting up the rolling mill, run test pieces to check your settings.

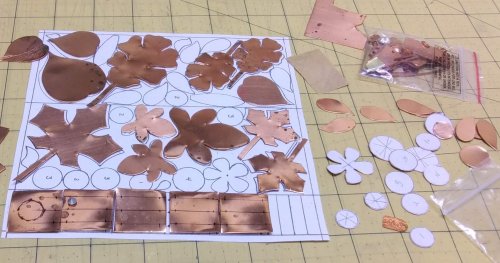

Cut several 1½" square pieces of copper sheet in each gauge you have.

Cut 2"x4½" manila or cardstock folders, folded in half for each piece.

Use the same texture for each test in my case, inexpensive cupcake wrappers.

Cut a texture sheet to fit each metal square. Circles are helpful to measure how much the impressed texture distorts, since roller printing elongates the image slightly.

Anneal half of the squares. Practice with and without using a folder.

Make notes on the back of each square and in your notebook.

**Not using a folder:**

Cut several 1½" square pieces of copper sheet in each gauge you have.

Cut 2"x4½" manila or cardstock folders, folded in half for each piece.

Use the same texture for each test in my case, inexpensive cupcake wrappers.

Cut a texture sheet to fit each metal square. Circles are helpful to measure how much the impressed texture distorts, since roller printing elongates the image slightly.

Anneal half of the squares. Practice with and without using a folder.

Make notes on the back of each square and in your notebook.

**Not using a folder:**

A: Open the rollers, place a square between the metal and then tighten the roller so the square will not pull out. Note the setting and remove the square.

B: If the noted setting number was 6, turn it back to 5½ or 5. Place the texture sheet on top of the metal. Run through the mill.

C: Make adjustments in the setting and roll another square through the mill. Continue until satisfied with the imprint. Do not tighten the rollers too much. The crank should be hard to turn but not so difficult that you need to ask for help to turn it.

Using a folder:

A: Open the rollers, place a square in the folder between the metal and then tighten the roller so the sandwich will not pull out. Note the setting and remove the square.

A: Open the rollers, place a square in the folder between the metal and then tighten the roller so the sandwich will not pull out. Note the setting and remove the square.

B: Continue as with B and C above.

Using craft foam:

Adding a piece of dense thin craft foam under the metal will help push the metal into the texture, creating a deeper impression. It is especially helpful when used with thinner gauge metals.:

Using metal plates for impressions:

Always place a folder or piece of cardstock under the metal plate. This will help keep the metal from damaging the rollers.

After all that practice, you should have a handle on what settings to start with when using other textures. Whenever using a new texture, start with a practice piece.

Adding a piece of dense thin craft foam under the metal will help push the metal into the texture, creating a deeper impression. It is especially helpful when used with thinner gauge metals.:

Using metal plates for impressions:

Always place a folder or piece of cardstock under the metal plate. This will help keep the metal from damaging the rollers.

After all that practice, you should have a handle on what settings to start with when using other textures. Whenever using a new texture, start with a practice piece.

After every use, the rollers should be cleaned

Step 1: Cut a ¾" dowel just shy of the width of the rollers. Sand the ends of the dowel smooth.

Cut an old cotton terry towel into pieces about the width of the dowel and 6 inches (15 cm) long.

Use a sewing machine to zig-zag stitch around the edges twice. Trim any loose fuzzies.

Wash and dry the finished pieces to remove extra terry loops that might fall off and get stuck in the rolling mill.

I'm a Cautious Nellie, so I ran mine through the washer and dryer twice.

Step 3: Fold the terry piece over the dowel.

Cut an old cotton terry towel into pieces about the width of the dowel and 6 inches (15 cm) long.

Use a sewing machine to zig-zag stitch around the edges twice. Trim any loose fuzzies.

Wash and dry the finished pieces to remove extra terry loops that might fall off and get stuck in the rolling mill.

I'm a Cautious Nellie, so I ran mine through the washer and dryer twice.

Step 3: Fold the terry piece over the dowel.

Step 4: Open the rollers one full turn of the calibration gear.

Swipe metal polish onto each roller.

Push the terry cloth ends through the rollers using the roller crank.

Adjust the rollers to allow both to turn mine needs one full turn plus 13 clicks.

Make a note of this setting to avoid guessing next time.

The terry cloth helps spread the polish evenly.

Turn the crank backward to remove the dowel and cloth.

Turn the cloth clean side out and repeat to remove excess polish while leaving a protective film against corrosion.

Swipe metal polish onto each roller.

Push the terry cloth ends through the rollers using the roller crank.

Adjust the rollers to allow both to turn mine needs one full turn plus 13 clicks.

Make a note of this setting to avoid guessing next time.

The terry cloth helps spread the polish evenly.

Turn the crank backward to remove the dowel and cloth.

Turn the cloth clean side out and repeat to remove excess polish while leaving a protective film against corrosion.

Step 5: I keep all my small terry pieces in a gallon-size resealable plastic bag.

Inside that bag is a smaller resealable bag for used cloths, which should only be used once, plus the dowel and polish.

The calibration setting needed for cleaning is written on the outside of the bag and on the first page of my notebook.

The bag is stored in a basket on the rolling mill stand.

Hint: I keep a tube of the same polish in my jewelry worktable drawer to clean, polish, and protect my metal tools regularly.

Inside that bag is a smaller resealable bag for used cloths, which should only be used once, plus the dowel and polish.

The calibration setting needed for cleaning is written on the outside of the bag and on the first page of my notebook.

The bag is stored in a basket on the rolling mill stand.

Hint: I keep a tube of the same polish in my jewelry worktable drawer to clean, polish, and protect my metal tools regularly.

Covering the rolling mill

When not in use, cover your rolling mill to keep dust and grit out of the works.

A side benefit is that little elves won't play with what they can't see or easily reach.

My cover has a Velcro strap on the back to hold it tightly in place.

Try to place the rolling mill in the least humid area of your workspace to protect it from moisture damage.

A side benefit is that little elves won't play with what they can't see or easily reach.

My cover has a Velcro strap on the back to hold it tightly in place.

Try to place the rolling mill in the least humid area of your workspace to protect it from moisture damage.

Things to remember

Annealed metal accepts better impressions than unannealed metal.

Some metals, like copper, are softer and usually give great impressions.

If your item is thin or lacks detail such as small dried leaves harvested in spring it's best to anneal the metal first.

Sandwiching the metal and texture inside a folder protects the rollers, though it's not always necessary.

Folders should be used when rolling dried organic textures or metal texture plates, as organic materials may contain corrosive oils.

For example, a craft glue stick was used to adhere leaves to typing paper slightly smaller than the metal piece.

The glue contains moisture, and even small amounts can damage the rollers, so it's better to be safe.

Small metal sheets and hardware store screen make great multi-use textures, but since their metals are unknown, using a rolling folder is wise.

Hint: Make rolling folders from old manila folders, which impart a slight matte finish to the metal. Cardstock can also be used.

Some metals, like copper, are softer and usually give great impressions.

If your item is thin or lacks detail such as small dried leaves harvested in spring it's best to anneal the metal first.

Sandwiching the metal and texture inside a folder protects the rollers, though it's not always necessary.

Folders should be used when rolling dried organic textures or metal texture plates, as organic materials may contain corrosive oils.

For example, a craft glue stick was used to adhere leaves to typing paper slightly smaller than the metal piece.

The glue contains moisture, and even small amounts can damage the rollers, so it's better to be safe.

Small metal sheets and hardware store screen make great multi-use textures, but since their metals are unknown, using a rolling folder is wise.

Hint: Make rolling folders from old manila folders, which impart a slight matte finish to the metal. Cardstock can also be used.

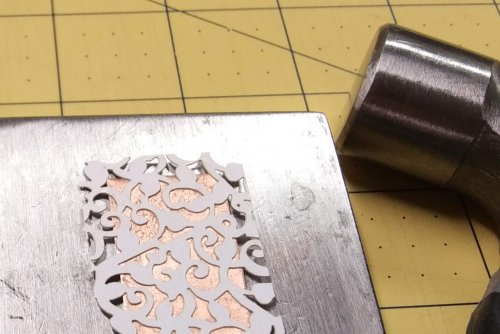

I love laser-cut designs. Although not generally advised, this process has worked well for me without problems.

To conserve metal, I cut the designs out and arrange them on a 2"x6" piece of metal.

I use only a small amount of craft glue stick on a corner of each piece to hold it in place.

The whole piece is then sandwiched inside a manila folder before running it through the mill.

The glue dries quickly, releasing the design from the metal, and the folder keeps everything in place.

Why glue should not be used: Even a tiny amount can leave an impression in the metal.

Even something as thin as baby's hair will impress into metal.

Plus, moisture in the glue is harmful to the rolling mill.

To conserve metal, I cut the designs out and arrange them on a 2"x6" piece of metal.

I use only a small amount of craft glue stick on a corner of each piece to hold it in place.

The whole piece is then sandwiched inside a manila folder before running it through the mill.

The glue dries quickly, releasing the design from the metal, and the folder keeps everything in place.

Why glue should not be used: Even a tiny amount can leave an impression in the metal.

Even something as thin as baby's hair will impress into metal.

Plus, moisture in the glue is harmful to the rolling mill.

Thinner metals would benefit from having a slightly larger piece of thin craft foam put behind them in the sandwich. The craft foam will push the metal into the piece being impressed, resulting in a better impression.

Do not cut a finished metal piece the size and shape desired for a finished piece before impressing a design. The metal will be stretched in length but negligibly in width when run through the mill. Keep that in mind when placing the designs on the sheet of metal.

Whatever is being sent through the rollers should be centered between the sides of the rollers. This will make for a more even impression and put less stress on one side or the other of the mill.

There needs to be enough pressure to imprint the metal, but not so much that you cannot turn the crank or need to ask for help to turn it. Too much stress on the rollers and gears over time can cause the mill the break.

Do not cut a finished metal piece the size and shape desired for a finished piece before impressing a design. The metal will be stretched in length but negligibly in width when run through the mill. Keep that in mind when placing the designs on the sheet of metal.

Whatever is being sent through the rollers should be centered between the sides of the rollers. This will make for a more even impression and put less stress on one side or the other of the mill.

There needs to be enough pressure to imprint the metal, but not so much that you cannot turn the crank or need to ask for help to turn it. Too much stress on the rollers and gears over time can cause the mill the break.

What can be used to make impressions on metal?

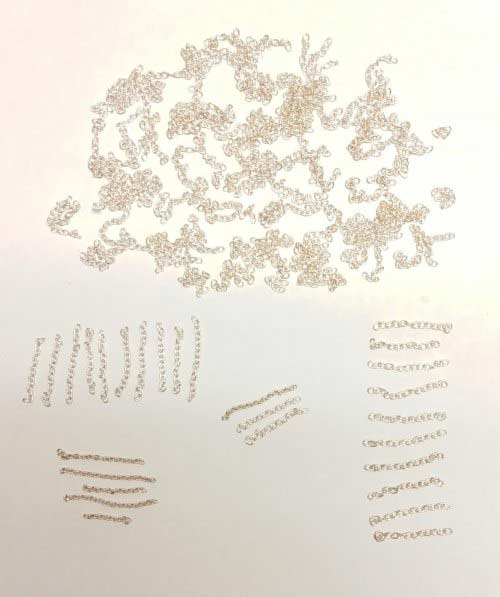

Almost anything flat and relatively thin can be usedjust make sure it's narrower than the roller width.

Pre-textured brass sheets made for jewelry can create multiple impressions before the designs lose crispness. They remain usable for jewelry making afterward.

Inexpensive laser-cut cupcake wrappers also make great impressions on metal.

Here, an 18-gauge strip, ¾" wide and 6" long, was rolled and stretched to 6½" long.

Because my rollers are narrow, the wrapper was trimmed to fit.

Pre-textured brass sheets made for jewelry can create multiple impressions before the designs lose crispness. They remain usable for jewelry making afterward.

Inexpensive laser-cut cupcake wrappers also make great impressions on metal.

Here, an 18-gauge strip, ¾" wide and 6" long, was rolled and stretched to 6½" long.

Because my rollers are narrow, the wrapper was trimmed to fit.

Mirror images can be obtained by sandwiching a design between two pieces of metal placed in a folder.

Imprint an allover pattern like the pieces on the left.

For the center and right pieces, the design was cut out, placed on the metal, and run through the mill.

Then the pieces were cut to the desired shape either centered or with a border, as shown on the right.

For the center and right pieces, the design was cut out, placed on the metal, and run through the mill.

Then the pieces were cut to the desired shape either centered or with a border, as shown on the right.

Heavy weave ribbons (with metal edge wire removed), plastic net sleeves from onions or turkeys, crushed paper grocery bags, designs cut from cardstock, lace, feathers, and many other materials will probably work.

Pinterest is full of creative ideas to try.

Pinterest is full of creative ideas to try.

Materials

24 Gauge 0.020 Dead Soft Copper Sheet Metal - 6x12 Inch

MET-705.24M

- Lesson Quantity: 1.00 pieces

- Purchase Quantity: 1.00 each

- Price: $11.90

- Gold Club Price: $8.93

Tools

Rolling Mill 80mm

MIL-280.10

- MIL-280.10

- Lesson Quantity: 1.00 pieces

- Purchase Quantity: 1.00 each

- Price: $349.95

- Gold Club Price: $262.46

- Category: Tools

- Technique(s): Tools

Coiled Wire Jewelry Series Part 1 - Everything New is Old

Coiled Wire Jewelry Series Part 1 - Everything New is Old

Where do you create

Where do you create

Soldering on Copper

Soldering on Copper

Charting Your Creations

Charting Your Creations

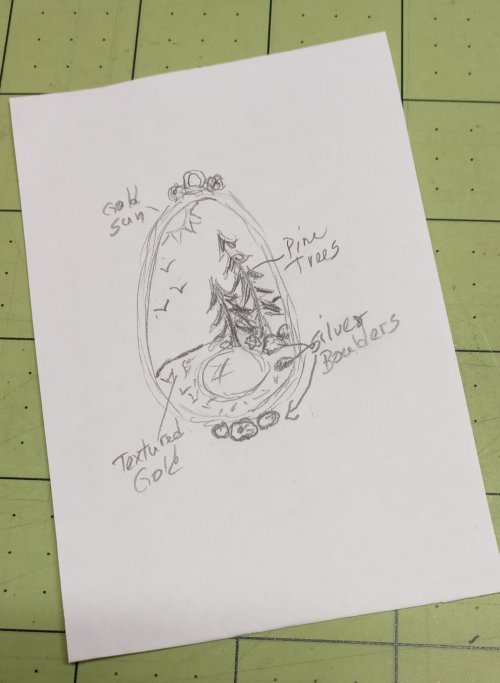

Design Process with 3 Earrings

Design Process with 3 Earrings

How to Use Disc Cutters to Make Metal Washers

How to Use Disc Cutters to Make Metal Washers

Disc Cutter Basics and How to Make Metal Washers

Disc Cutter Basics and How to Make Metal Washers

I Am Not a Hoarder

I Am Not a Hoarder

The Beauty of Druzy

The Beauty of Druzy

Design Process with 3 Different Earrings

Design Process with 3 Different Earrings

Think Outside the Box - Alternative Metal Texturing

Think Outside the Box - Alternative Metal Texturing

Fall Leaves for Your Designs

Fall Leaves for Your Designs

Cholula "Folk Art" Charms

Cholula "Folk Art" Charms

Lemons to Lemonade

Lemons to Lemonade

Why You Should Take a Class

Why You Should Take a Class

Bead, Shell, and Rock Cabochons

Bead, Shell, and Rock Cabochons

What Tools Do I Need for Wirework and Bead Stringing - Start With The Basics

What Tools Do I Need for Wirework and Bead Stringing - Start With The Basics

Choosing Pliers

Choosing Pliers

Saving, Storing, Using Tutorials

Saving, Storing, Using Tutorials

Flop to Flip

Flop to Flip

The Story of Turquoise

The Story of Turquoise

Non Marring Tools

Non Marring Tools

Using Lower Quality Beads

Using Lower Quality Beads

Differences in Gold Plating

Differences in Gold Plating

Inventorying Your Supplies

Inventorying Your Supplies

Engineering the Multi-chain Necklace

Engineering the Multi-chain Necklace

Benefits of Extender Chains

Benefits of Extender Chains

My Most Often Used Embellishments

My Most Often Used Embellishments

Sliding Gauges and Calipers

Sliding Gauges and Calipers

Wire and Sheet Gauge Measuring Tool

Wire and Sheet Gauge Measuring Tool

Silver Plated Copper Craft Wire

Silver Plated Copper Craft Wire

Jewelry from Other Cultures

Jewelry from Other Cultures

Conversation Starters

Conversation Starters

Well, That Didn't Work, Now What

Well, That Didn't Work, Now What

Water Casting for the Weekend Jeweler

Water Casting for the Weekend Jeweler

A Few Thoughts on Multi-Strand Beading Wires

A Few Thoughts on Multi-Strand Beading Wires

How to Downsize Your Earring Projects Without Losing Style

How to Downsize Your Earring Projects Without Losing Style

Celebration Jewelry

Celebration Jewelry