- NEW DVD Series – Stone Setting with Bezels

- Tube Set Charm by Kim St. Jean

- Prong Basket Pendant by Kim St. Jean

- NEW DVD Series – Stone Setting with Cold Connections

- New DVD Series – Stone Setting with Wire

- NEW DVD Series: Introduction to Stone Setting by Kim St. Jean

- Featured Tool: Bracelet Bending Plier

- NEW Dvd by Eva Sherman

- Fun, Fast Fold Forming DVD Series

- Double Band Ear Cuff from Alex Simkin

Daily Wire Tip for Oct. 12: Finding Draw Plate Gauge

Daily Wire Jewelry Making Tip for

October 12, 2011

Question:

Hi, I’m wondering what the gauges are in wire jewelry, and what the increment between each gauge is. I have a draw plate, but the holes aren’t marked, so I don’t know the sizes or increments. Thank you.

-Mollie in Reardan, Washington

Answer:

Hi Mollie, most wire jewelry uses gauges from 14-gauge (thick) to 28-gauge (thin), with some pieces and techniques using even larger and thinner wire. The higher the number, the thinner the wire; to help me remember, I think about a small tube that I put wire in, and I can fit lots of thin wire (like 28), but not as many thick ones (like 12). Wire jewelry patterns usually choose gauges from all the even-numbered gauges plus 21-gauge.

The wire sold in North America is usually measured according to the American Wire Gauge (AWG), one of a few ways to measure wire. Wikipedia has a lot of information on this measuring system, including how the steps between sizes are calculated and some rules of thumb.

Here on Wire-Sculpture, we have a handy page for finding the diameter (width) of the wire in inches and millimeters. Simply go to our Resource Center and look under All About Wire, it’s called Wire Gauge & Footage Charts. The first two charts are for converting weight of wire to footage (because some people are used to ordering wire by the ounce or the pound, and we offer jewelry wire by the foot); the last chart will help you convert AWG to inches and millimeters.

As far as your draw plate, to find what gauge a hole is, I would measure the diameter of the hole with a ruler that has millimeters, a wire gauge, or a caliper. Just use the chart I linked above to convert the millimeters to AWG. Be aware that many draw plates are chamfered, meaning that the hole is wider where you put it in, and tapers to be smaller as the finished size. I hope this helps!

Answer contributed by Rose Marion

Have a Question? Click Here to Submit Your Question

Click to Receive Daily Tips by Email

Dena Ellison

October 12, 2011 at 1:13 pm

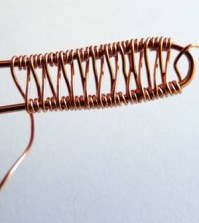

Another alternative would be to get a foot of each gauge of copper wire and try to put it through the draw plate from the back side. The smallest hole it will fit through is the hole for that gauge. Then, you can label each hole. You would really only need to get wire in the range you are likely to use.

Kathy C.

October 12, 2011 at 2:07 pm

I really appreciate the chart showing lengths and weights of wire. Does argentium sterling have the same weights per length as regular sterling?

Rose

October 14, 2011 at 4:01 pm

Hi Kathy, that’s a great suggestion! An Argentium Footage/Weight Chart is on my to-do list now, I’ll update that page with the charts as soon as I’ve researched and completed it. Thanks!